|

Capacity |

10--2000m3/h |

|

Head |

7--62m |

|

Medium temperature |

-20℃--60℃ |

|

Maximum pressure |

≤16bar |

YW submersible sewage pump adopts a unique submersible installation method, which can effectively reduce noise and vibration and ensure stable and long-lasting operation. The pump has strong sewage discharge capacity and can easily handle high concentration and high viscosity sewage, ensuring smooth and unobstructed discharge. Its compact structure and easy installation not only save space, but can also be put into use quickly, providing strong support for sewage treatment work.

Advantage:

1. YW submersible sewage pump has strong sewage discharge capacity and good equipment stability;

2. YW submersible sewage pump has excellent corrosion resistance;

3. YW submersible sewage pump has a compact structure and is simple and convenient to install;

4. YW submersible sewage pump has an intelligent control system.

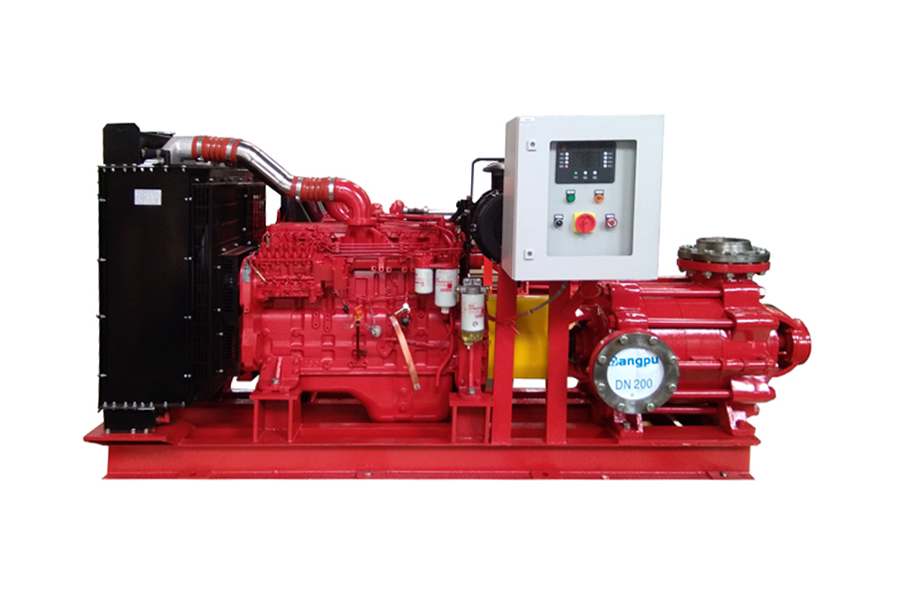

Shanghai Bangpu Industrial Group Co., Ltd. is a large group enterprise specializing in R & D and manufacturing all kinds of fluid transmission equipment in China. Since its establishment, the group has implemented diversified operation, with pumps, valves, energy-saving motors and complete sets of water supply and drainage equipment as its basic business, and the production, sales, import and export business of sewage treatment, environmental protection equipment and related accessories as its extension.

Shanghai Bangpu as China Custom YW under-liquid sewage pump Suppliers and OEM/ODM YW under-liquid sewage pump Company, it produces a variety of products with complete specifications. Its main products include frequency conversion and constant pressure water supply equipment, pipe network laminated water supply equipment, box-type laminated water supply equipment, remote monitoring system, water pumps and various electrical control equipment.

Since its establishment, through continuous competition with other complete sets of secondary water supply equipment manufacturers and continuous self-accumulation, the company has won the height of end users in terms of core technology, differentiated design customization, quality consistency assurance, and continuous and stable recognized.

On February 9, 2018, the signing and unveiling cer...

Read more

In recent days, it has generally cooled and snowed...

Read more

1. Electric motor fire pump set (9 series, a total...

Read more

The company participated in the China Urban Water ...

Read more

In January 2017, the company launched the environm...

Read more

In order to improve the corporate image, the compa...

Read more

In order to improve the product quality of the ent...

Read more

In order to meet the market demand, the company de...

Read more

Through unremitting efforts and many visits by cus...

Read more

In June 2017, in order to ensure the smooth commis...

Read more

On February 18, 2017, the annual company's annual ...

Read more

The group company has passed the re-certification ...

Read moreHigh-quality material selection: Manufacturers will use high-quality materials to manufacture YW submersible sewage pumps, such as corrosion-resistant cast iron, stainless steel, etc., to ensure that the pump body is not easily damaged in harsh working environments, thereby extending its service life.

Advanced manufacturing process: Adopt advanced manufacturing processes and technologies, such as precision casting, CNC machining, etc., to improve the manufacturing accuracy and reliability of YW submersible sewage pumps. These processes ensure that the various parts of the pump are tightly integrated, reducing the occurrence of leaks and failures.

Strict quality control: YW submersible sewage pump manufacturers will establish a strict quality control system to strictly control every production link of YW submersible sewage pumps. This includes raw material inspection, quality inspection during production and comprehensive testing of finished products before leaving the factory to ensure that each pump meets relevant standards and requirements.

Reasonable design structure: The design structure of the YW submersible sewage pump should be reasonable to reduce friction and resistance during operation. For example, optimized hydraulic design is used to improve pump efficiency; wear-resistant and corrosion-resistant bearings and seals are used to reduce leakage and wear.

Efficient cooling system: Long-term continuous operation may cause the YW submersible sewage pump to overheat. Therefore, manufacturers will design efficient heat dissipation systems, such as adding heat sinks, using high-quality heat dissipation materials, etc., to ensure that the temperature of the pump remains stable during long-term operation.

Intelligent monitoring and alarm system: In order to detect and solve potential problems in time, YW submersible sewage pump manufacturers will equip YW submersed sewage pumps with intelligent monitoring and alarm systems. These systems can monitor the operating status of the pump in real time, such as temperature, pressure, flow, etc., and issue alarms in time when abnormalities are found, so that timely measures can be taken for repair or adjustment.

Installation and location:

Make sure that the YW submersible sewage pump is installed vertically on the cover of the liquid tank and avoid placing it at an angle.

The sewage pump must be immersed in the liquid and must not be idle without liquid.

Check before use:

Before use, check whether the water pump is stuck and confirm whether the vortex direction of the motor is consistent with the required rotation of the pump.

Regularly check the circuit and overall working condition of the pump to make sure everything is working properly.

Cleaning and maintenance:

After each use, especially after handling thicker and more viscous slurries, the water pump should be placed in clean water for a few minutes to prevent sediments from leaving in the pump and ensure the cleanliness of the water pump.

Regularly inspect and clean the inside and outside of the pump to remove accumulated dirt and impurities.

Lubrication and replacement:

Under normal conditions, after every 300-500 hours of use of the pump, the oil in the oil chamber (such as 10-30# engine oil) should be added or replaced to maintain the good lubrication state of the mechanical seal and extend the service life of the mechanical seal.

Seal ring inspection:

The sealing ring between the impeller and the pump body has a sealing function. If the sealing ring is damaged, it will directly affect the performance of the pump. Therefore, the condition of the sealing ring should be checked regularly and replaced if necessary.

Dedicated management:

It is recommended that the water pump be managed and used by dedicated personnel, so that the working status of the pump can be better monitored and problems can be discovered and solved in a timely manner.

Recording and monitoring:

Record the maintenance and upkeep of the pump, including the date of oil change, cleaning date, seal ring replacement date, etc.

Monitor pump operating data such as flow, head, current, etc. to evaluate pump performance and potential problems.