LPT vertical sewage pump is mainly used to pump sewage or wastewater with no corrosion, temperature below 60℃, and suspended solids (without fibers and non-abrasive particles) content of less than 150mg/L. It can pump sewage or waste water whose temperature is lower than 60℃ and contains certain solid particles (such as iron filings, fine sand, coal powder, etc.). Widely used in municipal engineering, metallurgical steel, mining, chemical papermaking, tap water, power plants and farmland water conservancy projects. The pulley can be easily replaced to change the speed of the pump to meet the change of the working condition or the change of the performance of the pump after wear. The suction port of the pump body is equipped with a filter screen, which can prevent large particles from entering the pump.

|

Capacity |

15--3000m3/h |

|

Head |

6--60m |

|

Medium temperature |

0℃--60℃ |

|

Maximum pressure |

≤16bar |

LP long-axis vertical drainage pump adopts a vertical structure, and the long-axis design makes it perform well when dealing with drainage of deep wells or large water bodies. The pump body is sturdy and durable and can operate stably for a long time, effectively ensuring the smooth progress of drainage work. LP long-axis vertical drainage pump adopts multiple protection measures, including overload protection, overheating protection, etc., to ensure the safety and reliability of the equipment during operation. At the same time, the pump also has high corrosion resistance, is suitable for a variety of harsh environments, and extends its service life.

Install:

Preparation before installation

1. When choosing an installation location, pay attention to the fact that it needs to be in a ventilated and dry room, preferably close to the drainage outlet;

2. Check whether the pump body, motor and all accessories are intact.

installation steps

1. Install the flow-passing parts of the vertical long-axis pump section by section from bottom to top according to the example of the structure diagram, ensuring that the connections between the components are tight and correct.

2. Add a pair of wedge pads between the bottom of the outlet elbow and the foundation to ensure that the pump body is stable.

3. Use concrete to pour the anchor bolts. After the concrete is dry, check the levelness of the flange plane on the top of the motor support to ensure that the anchor bolts are not loose.

4. Configure cooling water pipes as needed (if the water pump is not shown in the structure diagram, a cooling water pipe needs to be installed).

5. Adjust the adjusting nut on the upper part of the thrust bearing or the pump coupling to lift the rotor. The lifting amount is 1/2 of the total deflection of the rotor.

6. Adjust the jackscrew on the motor base to adjust the center of the motor coupling to ensure coaxiality between the motor and the pump body.

7. Check the coupling runout

8. Wiring and electrical installation

9. Inspection and Debugging

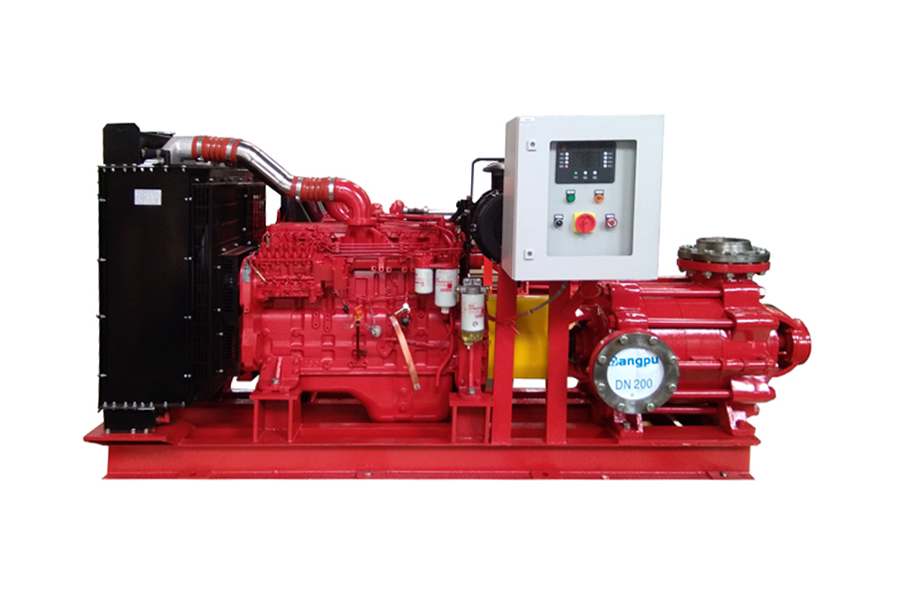

Shanghai Bangpu Industrial Group Co., Ltd. is a large group enterprise specializing in R & D and manufacturing all kinds of fluid transmission equipment in China. Since its establishment, the group has implemented diversified operation, with pumps, valves, energy-saving motors and complete sets of water supply and drainage equipment as its basic business, and the production, sales, import and export business of sewage treatment, environmental protection equipment and related accessories as its extension.

Shanghai Bangpu as China Custom LP long axial vertical drainage pump Suppliers and OEM/ODM LP long axial vertical drainage pump Company, it produces a variety of products with complete specifications. Its main products include frequency conversion and constant pressure water supply equipment, pipe network laminated water supply equipment, box-type laminated water supply equipment, remote monitoring system, water pumps and various electrical control equipment.

Since its establishment, through continuous competition with other complete sets of secondary water supply equipment manufacturers and continuous self-accumulation, the company has won the height of end users in terms of core technology, differentiated design customization, quality consistency assurance, and continuous and stable recognized.

On February 9, 2018, the signing and unveiling cer...

Read more

In recent days, it has generally cooled and snowed...

Read more

1. Electric motor fire pump set (9 series, a total...

Read more

The company participated in the China Urban Water ...

Read more

In January 2017, the company launched the environm...

Read more

In order to improve the corporate image, the compa...

Read more

In order to improve the product quality of the ent...

Read more

In order to meet the market demand, the company de...

Read more

Through unremitting efforts and many visits by cus...

Read more

In June 2017, in order to ensure the smooth commis...

Read more

On February 18, 2017, the annual company's annual ...

Read more

The group company has passed the re-certification ...

Read moreChoose high-efficiency motors:

Manufacturers will give priority to certified high-efficiency motors, such as IE2 or IE3 rated motors. These motors are designed with a focus on improving efficiency and reducing energy consumption.

They will evaluate different makes and models of motors and select those that have excellent performance, high efficiency, and are suitable for LP long-shaft vertical drainage pump applications.

Optimize the matching of motor and pump:

The manufacturer will ensure that the motor and drainage pump are optimally matched in terms of power, speed, torque, etc. to maximize the efficiency of the entire system.

They will use professional calculations and software simulations to determine the best motor and pump combination.

Using new materials and advanced technologies:

LP long-axis vertical drainage pump manufacturers will pay attention to the development of new materials and advanced technologies, such as the use of high-performance electromagnetic materials, optimized motor design, advanced control technology, etc., to improve the efficiency and performance of the motor.

These new materials and technologies can help reduce energy loss in motors and improve conversion efficiency.

Strict quality control:

LP long-axis vertical drainage pump manufacturers will establish a strict quality control system and conduct strict inspections and tests on purchased motors to ensure that their performance meets the design requirements.

During the production process, the quality of the motors will also be continuously monitored and evaluated to ensure the stability of product quality.

Regular technology upgrades and improvements:

Manufacturers will pay attention to changes in the market and technology, and regularly carry out technical upgrades and improvements to their products to adapt to changing market needs and technical requirements.

They research new motor technologies and materials and try to apply them into products to improve their performance and efficiency.

Whether the manufacturer of LP long-axis vertical drainage pump has conducted special tests or improvements on the motor and transmission system for long-term operational stability depends on the specific manufacturer and its product design and quality control processes.

Generally speaking, in order to ensure the quality and performance of products, many manufacturers will conduct a series of tests and improvement measures, especially on key components such as motors and transmission systems. These tests may include durability testing, reliability testing, load testing, etc. to ensure that these components can maintain stable performance and long service life under long-term operation.

However, specific to the manufacturer of the LP long-shaft vertical dewatering pump, I cannot directly provide information on whether it has conducted special testing or improvements for the long-term operating stability of the motor and transmission system. This may require you to contact the relevant manufacturer directly or check its official website, product manual, etc. to obtain more accurate information.