About Bangpu

Marvelous Design Meets Rigorous Manufacturing

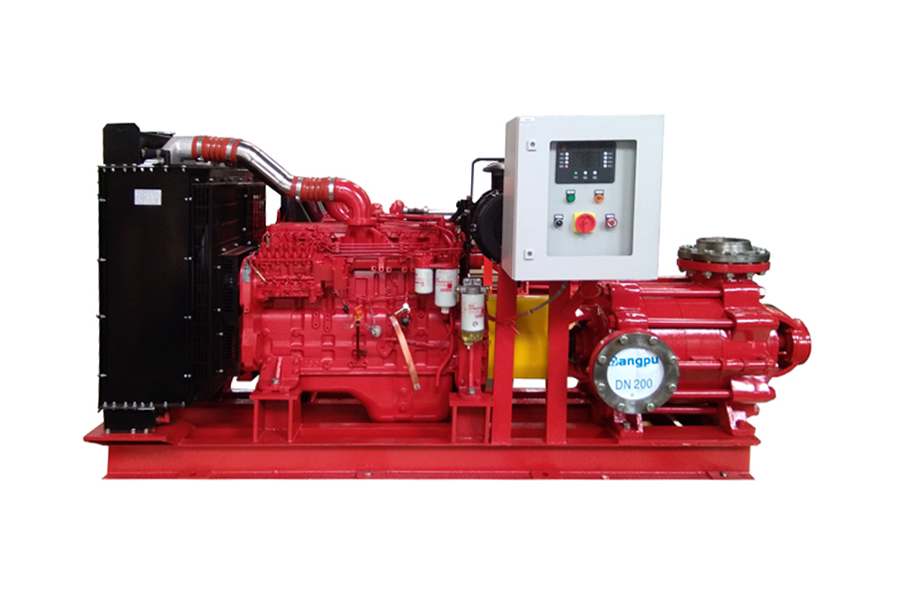

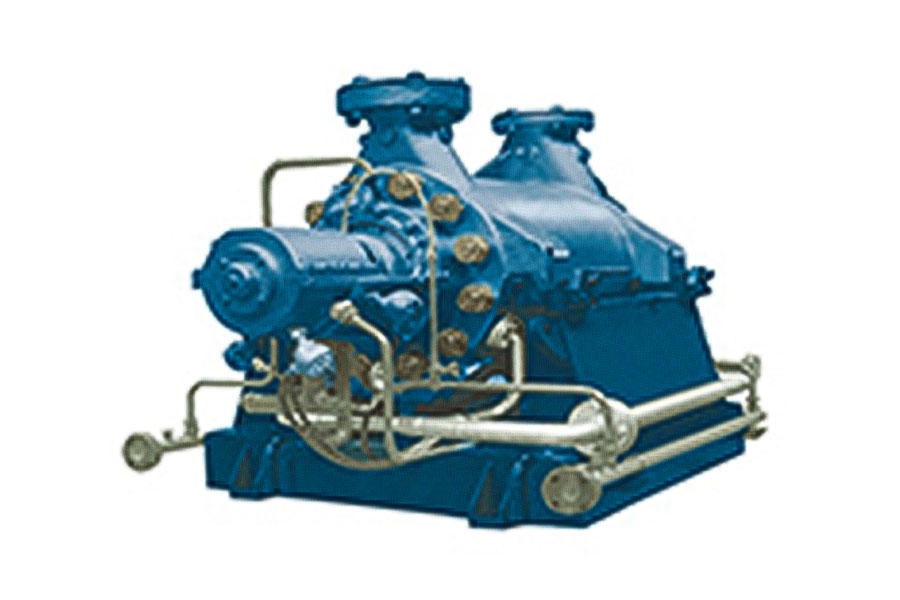

Shanghai Bangpu Industrial Group Co., Ltd. is a large group enterprise specializing in R & D and manufacturing all kinds of fluid transmission equipment in China. Since its establishment, the group has implemented diversified operation, with pumps, valves, energy-saving motors and complete sets of water supply and drainage equipment as its basic business, and the production, sales, import and export business of sewage treatment, environmental protection equipment and related accessories as its extension.

Shanghai Bangpu as China Custom AFP submersible sewage pump Suppliers and OEM/ODM AFP submersible sewage pump Company, it produces a variety of products with complete specifications. Its main products include frequency conversion and constant pressure water supply equipment, pipe network laminated water supply equipment, box-type laminated water supply equipment, remote monitoring system, water pumps and various electrical control equipment.

Since its establishment, through continuous competition with other complete sets of secondary water supply equipment manufacturers and continuous self-accumulation, the company has won the height of end users in terms of core technology, differentiated design customization, quality consistency assurance, and continuous and stable recognized.

English

English 中文简体

中文简体

Home

Home