|

Capacity |

10--6000m3/h |

|

Head |

6--62m |

|

Medium temperature |

0℃--60℃ |

|

Maximum pressure |

≤16bar |

The vertical sewage pump has excellent corrosion resistance and wear resistance, and can operate stably in harsh working environments. Its powerful sewage discharge capacity can quickly and effectively remove impurity particles in sewage to ensure smooth and efficient sewage discharge. Its efficient heat dissipation design ensures that the pump can maintain a stable operating temperature even when working continuously for a long time, extending the service life of the pump. In addition, the WL vertical sewage pump also has an intelligent control system, which can automatically adjust the operating status of the pump according to actual work needs to achieve energy saving and consumption reduction.

Installation process:

1. Prepare all necessary tools and materials, such as cement, steel bars, water pipes, etc.;

2. Select a suitable location for installing the WL vertical sewage pump;

3. According to the pump room design drawings, determine the installation position of the pump and ensure that the foundation plane is level;

4. Solidify base cement;

5. Place the pump on the foundation and use a level detector to check the level; if it is not flat, you need to place iron sheets on the foundation for adjustment until the pump is completely level;

6. Connect the pipes according to the inlet diameter of the pump;

7. Install electrical circuits;

8. Preliminary inspection. Make sure the electrical wiring is plugged in correctly, that the current to the pump is stable, and that the pump is turning correctly (clockwise). At the same time, check whether the pipelines of the sewage pump are normal and smooth, and there are no blockages or leaks.

9. Carry out trial operation and debugging of the pump.

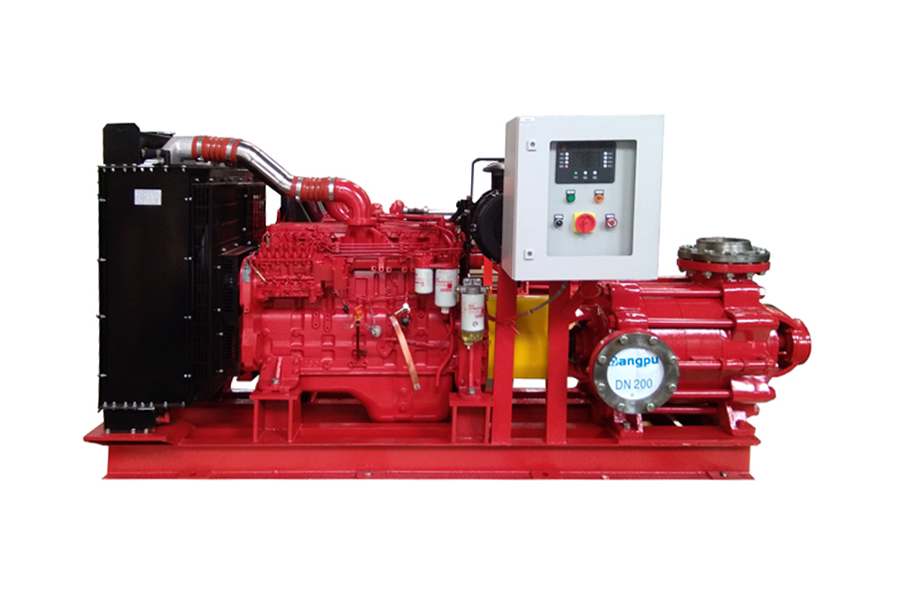

Shanghai Bangpu Industrial Group Co., Ltd. is a large group enterprise specializing in R & D and manufacturing all kinds of fluid transmission equipment in China. Since its establishment, the group has implemented diversified operation, with pumps, valves, energy-saving motors and complete sets of water supply and drainage equipment as its basic business, and the production, sales, import and export business of sewage treatment, environmental protection equipment and related accessories as its extension.

Shanghai Bangpu as China Custom WL vertical sewage pump Suppliers and OEM/ODM WL vertical sewage pump Company, it produces a variety of products with complete specifications. Its main products include frequency conversion and constant pressure water supply equipment, pipe network laminated water supply equipment, box-type laminated water supply equipment, remote monitoring system, water pumps and various electrical control equipment.

Since its establishment, through continuous competition with other complete sets of secondary water supply equipment manufacturers and continuous self-accumulation, the company has won the height of end users in terms of core technology, differentiated design customization, quality consistency assurance, and continuous and stable recognized.

On February 9, 2018, the signing and unveiling cer...

Read more

In recent days, it has generally cooled and snowed...

Read more

1. Electric motor fire pump set (9 series, a total...

Read more

The company participated in the China Urban Water ...

Read more

In January 2017, the company launched the environm...

Read more

In order to improve the corporate image, the compa...

Read more

In order to improve the product quality of the ent...

Read more

In order to meet the market demand, the company de...

Read more

Through unremitting efforts and many visits by cus...

Read more

In June 2017, in order to ensure the smooth commis...

Read more

On February 18, 2017, the annual company's annual ...

Read more

The group company has passed the re-certification ...

Read moreHigh-quality material selection: High-strength, corrosion-resistant materials are used to manufacture the pump body and key components to cope with chemical corrosion, physical wear and other problems in harsh environments.

Advanced design: Improve pump efficiency and reliability by optimizing the design structure. For example, a reasonable flow channel design is used to reduce fluid resistance and increase the lift and flow rate of the pump; a reliable sealing structure is used to prevent leakage and ensure the stable operation of the pump under harsh conditions such as high pressure and high temperature.

Strict quality control: During the manufacturing process, strict quality control measures are implemented to ensure that the quality of each component and the complete machine meets standard requirements. Through rigorous inspection and testing, the performance and reliability of the pump are ensured.

Protection design: Based on the characteristics of harsh environments, special protection designs are adopted. For example, design a waterproof, dustproof, and anti-corrosion protective cover for the motor; design an anti-freeze and anti-clogging structure for the pump body, etc.

Intelligent monitoring: Equipped with an intelligent monitoring system to monitor the operating status of the pump in real time, including temperature, pressure, flow and other parameters. When an abnormality occurs, the system can automatically alarm and take corresponding protective measures to ensure the safe operation of the pump.

Complete after-sales service: Provide a complete after-sales service system, including installation guidance, debugging, maintenance, maintenance, etc. When customers encounter problems, they can respond quickly and provide professional technical support and solutions.

Media characteristics:

Corrosive media: If the transported media is corrosive, the impeller material needs to have good corrosion resistance. For example, stainless steel, acid-resistant ferrosilicon, bronze and other materials are good choices for corrosion resistance.

Non-corrosive media: For non-corrosive media, you can choose materials such as cast iron or cast steel. These materials are relatively low-cost and have high strength and wear resistance.

Operating temperature:

Low temperature environment: Impellers working in low temperature environments need to choose materials with good low temperature toughness, such as stainless steel.

High temperature environment: When the impeller needs to work in a high temperature environment, materials such as heat-resistant alloy or high-temperature high-strength stainless steel with good high-temperature stability should be selected.

Pressure and speed:

High-pressure environment: For impellers that need to withstand high pressure, materials with higher pressure resistance should be selected, such as cast steel.

High speed: High-speed impellers need to choose materials with low density and good wear resistance to reduce friction and wear.

Economical and processability:

Cast iron material: Cast iron is a common water pump impeller material. It has the characteristics of low cost, easy processing and high strength, and is suitable for small and medium-sized water pumps.

Plastic material: Plastic material has the characteristics of excellent corrosion resistance, not easy to age, and light weight. It is also easy to process into various shapes and structures, but in some applications additional strengthening processing may be required.

Specific requirements:

Wear resistance: For impellers that require frequent contact with granular media, materials with good wear resistance should be selected, such as ceramics.

High temperature resistance: If the impeller needs to work in a high temperature environment, high temperature resistant materials should be selected to ensure its long-term stable operation.