An electric fire-fighting pump is a vital component of fire protection systems that is specifically designed to provide water flow and pressure to extinguish fires. It is powered by electricity and plays a crucial role in quickly and efficiently supplying water to the fire location. The primary function of an electric fire-fighting pump is to support fire suppression efforts by delivering a reliable water supply to the fire hose or sprinkler system.

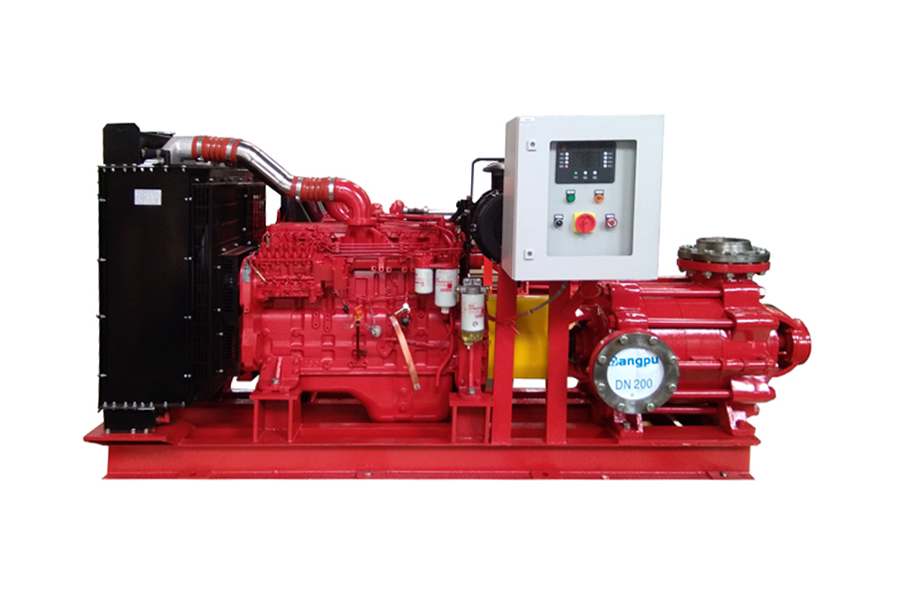

The key elements of an electric fire-fighting pump include an electric motor, pump assembly, control panel, and associated piping and valves. Here's an overview of how these components work together to fulfill the primary function:

Electric Motor: The electric motor is responsible for driving the pump and converting electrical energy into mechanical energy. It typically operates on AC power and is sized according to the specific requirements of the fire-fighting system. The motor is designed to provide sufficient power and torque to drive the pump at the required speed.

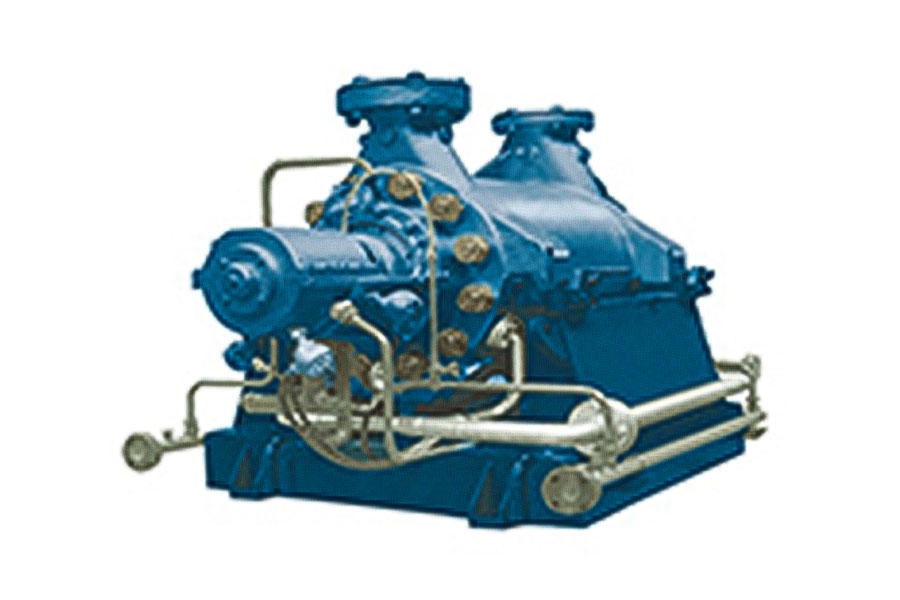

Pump Assembly: The pump assembly consists of an impeller, casing, and housing. The impeller is mounted on the motor shaft and rotates at high speed, creating a centrifugal force that imparts energy to the water. As water enters the pump through the suction inlet, it is accelerated by the impeller and propelled through the discharge outlet at high pressure.

Control Panel: The control panel houses the electrical components that govern the operation of the electric fire-fighting pump. It includes switches, indicators, and protective devices to monitor and control the pump's operation. The control panel enables operators to start, stop, and monitor the pump, as well as detect and respond to any faults or malfunctions.

Piping and Valves: The electric fire-fighting pump is connected to a network of piping and valves that distribute water to the fire hose or sprinkler system. These components are designed to withstand the high pressures and flows generated by the pump. Valves, such as gate valves or pressure relief valves, are strategically placed to control the flow and pressure within the system.

The primary function of an electric fire-fighting pump is to provide a reliable and adequate water supply to combat fires. It is capable of generating high pressures and flows to effectively extinguish flames, cool down surfaces, and control the spread of fire. Electric fire-fighting pumps are commonly used in various settings, including commercial buildings, industrial facilities, residential complexes, and public institutions.

In addition to their primary function of supplying water, electric fire-fighting pumps also serve as a backup in case the main water supply is compromised or insufficient. They can draw water from alternative sources such as tanks, ponds, or reservoirs, ensuring a continuous water supply during emergencies.

Furthermore, electric fire-fighting pumps can be integrated with fire alarm systems to automatically activate in response to a fire event. This enhances the speed and effectiveness of the fire suppression efforts, as the pump can be quickly deployed to the affected area.

Overall, an electric fire-fighting pump is an essential component of fire protection systems. Its primary function is to provide a reliable water supply, driven by an electric motor, to extinguish fires and protect lives and property. The design and operation of these pumps are crucial in ensuring the readiness and efficiency of fire suppression efforts in a wide range of settings.

English

English 中文简体

中文简体

Home

Home