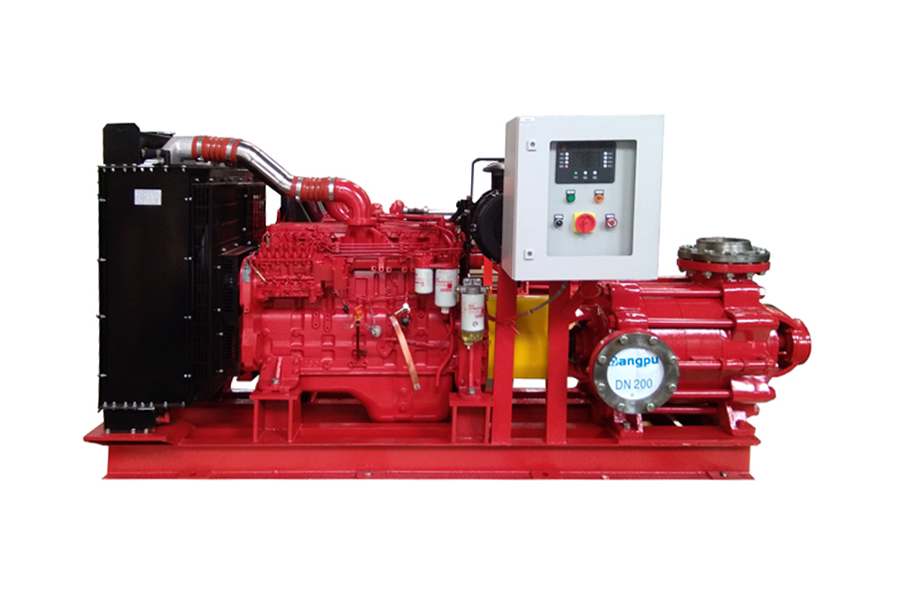

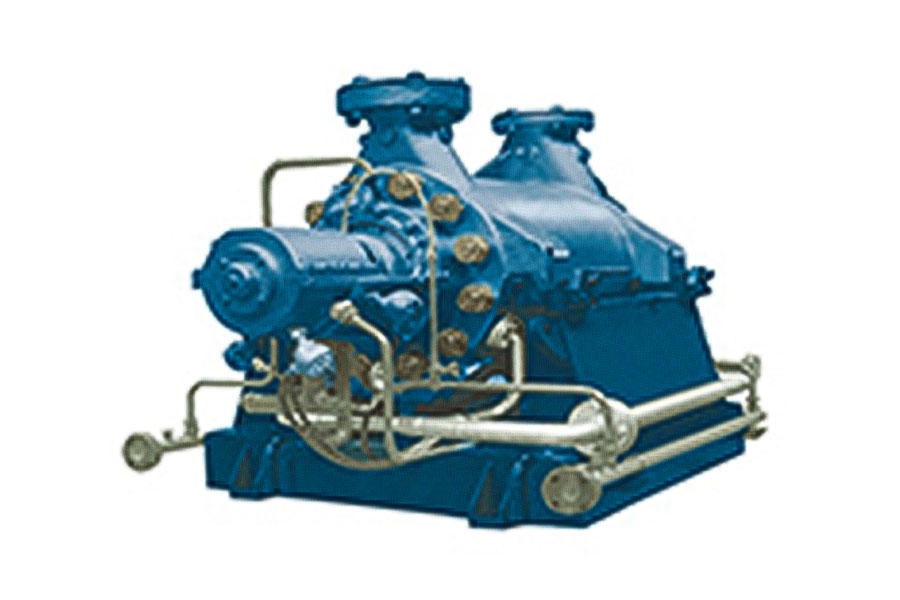

Electric fire-fighting pumps and diesel-driven fire-fighting pumps are two common types of pumps used in fire protection systems. While they both serve the same fundamental purpose of supplying water for fire suppression, there are several notable differences between them. Here's a closer look at how an electric fire-fighting pump differs from a diesel-driven pump:

Power Source:

One of the primary distinctions between the two types of pumps is the power source they utilize. An electric fire-fighting pump is powered by electricity, typically from the local power grid or an on-site generator. On the other hand, a diesel-driven fire-fighting pump is powered by a diesel engine, which runs on diesel fuel. This distinction in power source has implications for their availability, reliability, and ease of operation.

Operation and Start-up:

Electric fire-fighting pumps are relatively easier to operate and start up. They can be quickly activated with a simple switch or control panel, requiring minimal manual intervention. In contrast, diesel-driven pumps often require more effort to start, as they involve starting the diesel engine, priming the system, and ensuring proper fuel supply. Diesel engines may also require regular maintenance, such as fueling, oil changes, and filter replacements.

Fuel Availability:

An electric fire-fighting pump relies on the availability of electricity, which is typically readily available in most urban and developed areas. As long as there is a stable power supply or a backup generator, the electric pump can be operational. Conversely, diesel-driven pumps rely on a constant supply of diesel fuel, which may need to be stored on-site. This requires periodic refueling and consideration of fuel storage safety and regulations.

Noise and Emissions:

Electric fire-fighting pumps tend to operate more quietly compared to diesel-driven pumps, which produce noise and vibrations due to the combustion process in the diesel engine. Diesel engines also generate exhaust emissions, including particulate matter and nitrogen oxides. In certain settings, noise and emissions may be a consideration for selecting the appropriate pump type.

Maintenance and Service:

Both electric and diesel-driven pumps require regular maintenance to ensure their optimal performance. However, the maintenance requirements may differ. Diesel engines typically require more frequent servicing, including oil changes, fuel system maintenance, and periodic testing. Electric pumps, on the other hand, may have fewer moving parts and require less routine maintenance. However, electrical components and control panels need to be inspected and tested periodically.

Deployment Flexibility:

Electric fire-fighting pumps are generally suitable for fixed installations or locations with reliable power sources. They are commonly used in buildings, industrial facilities, and other structures connected to the electrical grid. Diesel-driven pumps offer more flexibility in deployment, as they can be used in remote locations or areas where a stable electrical supply is not available. This makes diesel-driven pumps suitable for temporary fire-fighting setups or in areas prone to power outages.

Cost Considerations:

The cost considerations of electric and diesel-driven pumps differ. Electric pumps typically have lower initial costs and require less infrastructure, as they rely on existing electrical connections. However, the cost of electricity consumption should be considered for long-term operation. Diesel-driven pumps have higher initial costs due to the diesel engine and associated fuel storage requirements. However, the ongoing operational costs may be lower in situations where fuel costs are relatively lower than electricity costs.

In summary, electric fire-fighting pumps and diesel-driven pumps differ in terms of power source, operation, start-up, fuel availability, noise and emissions, maintenance requirements, deployment flexibility, and cost considerations. The choice between the two depends on various factors, including the specific needs of the fire protection system, availability of power sources, noise and emission restrictions, maintenance capabilities, and budget considerations. Consulting with fire protection professionals and adhering to local regulations can help determine the most suitable type of fire-fighting pump for a particular application.

English

English 中文简体

中文简体

Home

Home