One of the important reasons why vertical multi-stage fire pumps can stand out among many fire protection equipment is its wide range of application scenarios. In various engineering construction enterprises and institutions, whether it is a fixed fire protection system, a high-rise building indoor fire hydrant fire extinguishing system, or an automatic sprinkler fire extinguishing system, vertical multi-stage fire pumps can perform excellently.

In fixed fire protection systems, vertical multi-stage fire pumps are usually used as the main water supply equipment. Their efficient and stable working state ensures that the fire protection system can respond quickly and provide sufficient water in an emergency. In the indoor fire hydrant fire extinguishing system of high-rise buildings, vertical multi-stage fire pumps are even more indispensable. Due to the height and complexity of high-rise buildings, traditional fire protection equipment often cannot meet the needs of high-pressure water delivery. The vertical multi-stage fire pump can easily meet the required high pressure requirements through the multi-stage booster design, ensuring that the fire hydrant can provide a strong water flow at a critical moment and effectively control the fire.

In the automatic sprinkler fire extinguishing system, the vertical multi-stage fire pump also plays an important role. The automatic sprinkler fire extinguishing system is an intelligent fire-fighting equipment that can automatically start when a fire occurs and extinguish the flames by spraying water mist through the nozzle. The efficient water supply capacity of the vertical multi-stage fire pump ensures that the automatic sprinkler fire extinguishing system can be quickly started when a fire occurs, providing a stable water source, thereby effectively controlling the spread of the fire.

In addition to the above application scenarios, vertical multi-stage fire pumps are also widely used in fire protection systems in industrial plants, warehouses, shopping malls, hospitals and other places. Its flexible installation method and strong water supply capacity make the fire protection systems in these places more perfect, providing a more solid guarantee for the safety of people's lives and property.

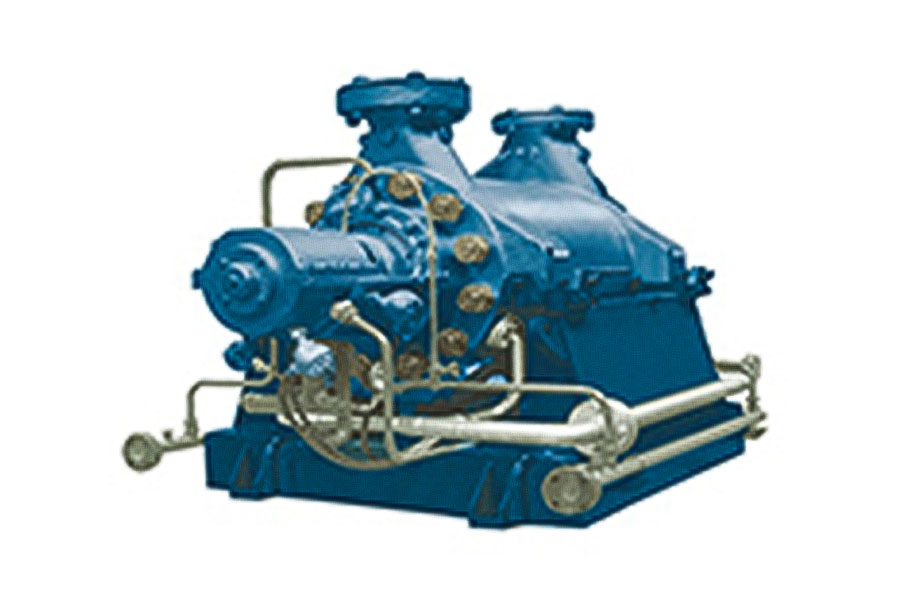

The reason why vertical multi-stage fire pumps can be widely used in various fire protection systems is not only due to its wide range of application scenarios, but also due to its excellent performance characteristics. Efficient and stable working state is one of the important features of vertical multi-stage fire pumps. The design of its multi-stage impeller enables the water flow to be pressurized multiple times to achieve the required high pressure requirements. At the same time, the vertical multi-stage fire pump also uses advanced materials and manufacturing processes to ensure the strength and wear resistance of the pump body and extend the service life of the equipment.

In addition, the vertical multi-stage fire pump also has the following performance characteristics:

Energy saving and environmental protection: The vertical multi-stage fire pump can maintain low energy consumption during operation, reducing energy waste. At the same time, its noise and vibration levels are relatively low, and the pollution to the environment is small.

Easy to maintain: The vertical multi-stage fire pump has a compact and simple structure, making maintenance and maintenance more convenient. At the same time, the versatility of its parts is also high, reducing maintenance costs.

Strong adaptability: The vertical multi-stage fire pump can be applied to a variety of media and working conditions, such as conveying clean water, sewage, corrosive liquids, etc. At the same time, its working pressure and flow range are also wide, which can meet the needs of different occasions.

These performance characteristics enable the vertical multi-stage fire pump to perform excellent performance in various fire protection systems and provide strong support for fire response.

The reason why the vertical multi-stage fire pump can occupy an important position in the field of fire protection is inseparable from the technical advantages behind it. With the continuous development of science and technology, vertical multi-stage fire pumps are also constantly innovating in design and manufacturing, making their performance more outstanding.

In terms of materials, vertical multi-stage fire pumps use high-strength and corrosion-resistant materials such as stainless steel and alloy steel. These materials not only improve the strength and wear resistance of the pump body, but also extend the service life of the equipment. These materials also have good corrosion resistance and can be applied to a variety of media and working conditions.

In terms of manufacturing technology, vertical multi-stage fire pumps use advanced casting, welding and heat treatment processes. These processes not only improve the manufacturing accuracy and surface quality of the pump body, but also ensure the stability and reliability of the equipment. These processes also reduce manufacturing costs and improve the cost performance of the equipment.

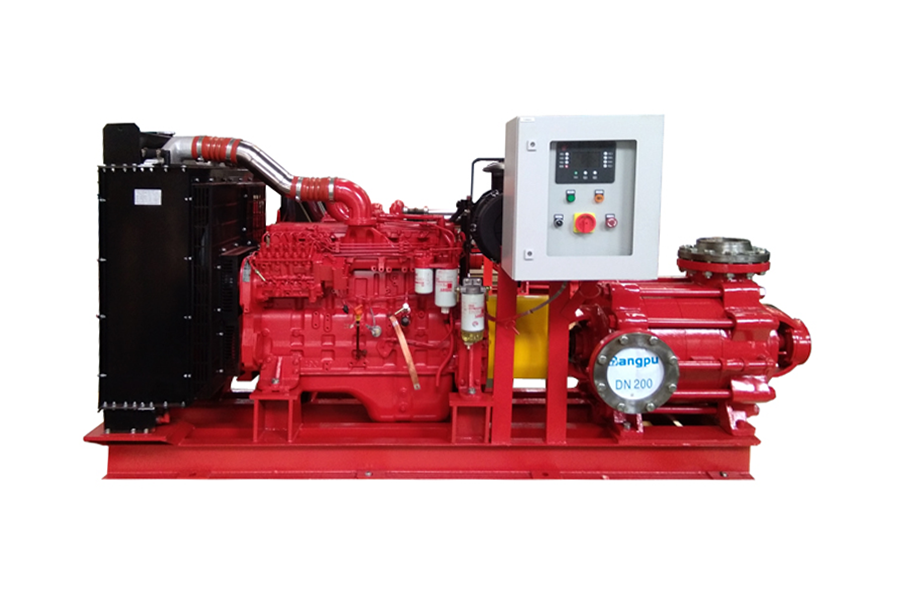

In terms of control technology, vertical multi-stage fire pumps have also made significant progress. Modern vertical multi-stage fire pumps are usually equipped with advanced control systems and sensors that can monitor the operating status and parameters of the equipment in real time. When the equipment fails or abnormal conditions occur, the control system can quickly issue an alarm and take corresponding measures to ensure the safe operation of the equipment. At the same time, these control systems can also realize functions such as remote monitoring and intelligent control, which improves the intelligence level of the equipment.

These technical advantages make vertical multi-stage fire pumps more outstanding in performance and provide more reliable support for various fire protection systems. These technical advantages have also promoted the widespread application and development of vertical multi-stage fire pumps in the fire protection field.

English

English 中文简体

中文简体

Home

Home