The core advantages of wear-resistant centrifugal mine water pumps are first reflected in the selection of their manufacturing materials. Different from ordinary metals or alloys used in ordinary water pumps, wear-resistant centrifugal mine water pumps use high-strength, wear-resistant alloy materials. This material has excellent mechanical properties and anti-wear properties, allowing it to maintain structural stability and integrity under extreme working conditions.

Specifically, high-strength wear-resistant alloy materials have the following significant characteristics:

High hardness: The hardness of wear-resistant alloy materials is much higher than that of ordinary metals, which can effectively resist the erosion and wear of solid particles in the slurry and reduce the wear of the equipment surface.

High strength: When withstanding the impact of high-pressure, high-flow fluids, wear-resistant alloy materials can maintain good resistance to deformation, ensuring the overall structural stability of the water pump.

Corrosion resistance: During the slurry transportation process, the fluid often contains corrosive substances. Wear-resistant alloy materials have excellent corrosion resistance and can protect the inside of the water pump from corrosion.

In addition to high-quality material selection, wear-resistant centrifugal mine water pumps also undergo special treatment on key components such as pump bodies, impellers, etc. to further enhance their wear resistance.

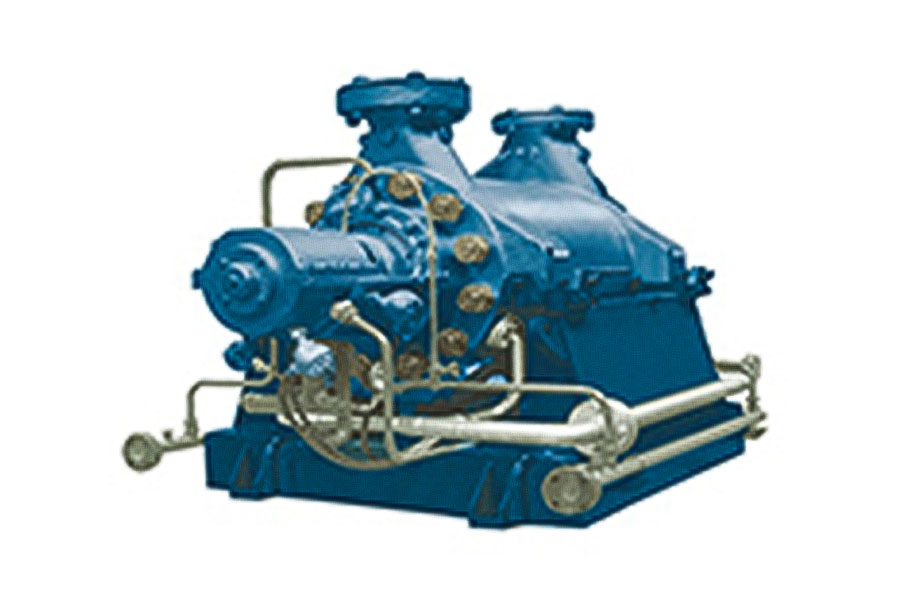

Pump body treatment: The pump body is the main structure of the water pump, which bears the fluid pressure and the erosion of solid particles. The pump body of a wear-resistant centrifugal mine water pump is usually made by casting or forging process, and the surface is treated with wear-resistant coating. This coating has high hardness and good adhesion, forming a protective layer to effectively resist wear and corrosion.

Impeller treatment: The impeller is the power component of the water pump, and its performance directly affects the flow and lift of the water pump. The impeller of a wear-resistant centrifugal mine water pump is usually made by precision casting or welding process, and is hardened on the surface. Hardening treatment can increase the hardness and wear resistance of the impeller and reduce wear caused by erosion of solid particles.

Seal treatment: The water pump seal is a key component to prevent fluid leakage. The seals of wear-resistant centrifugal mine water pumps are usually made of high-performance materials, such as silicon carbide, tungsten carbide, etc. These materials have excellent wear resistance and corrosion resistance and can ensure a long-lasting and stable sealing effect.

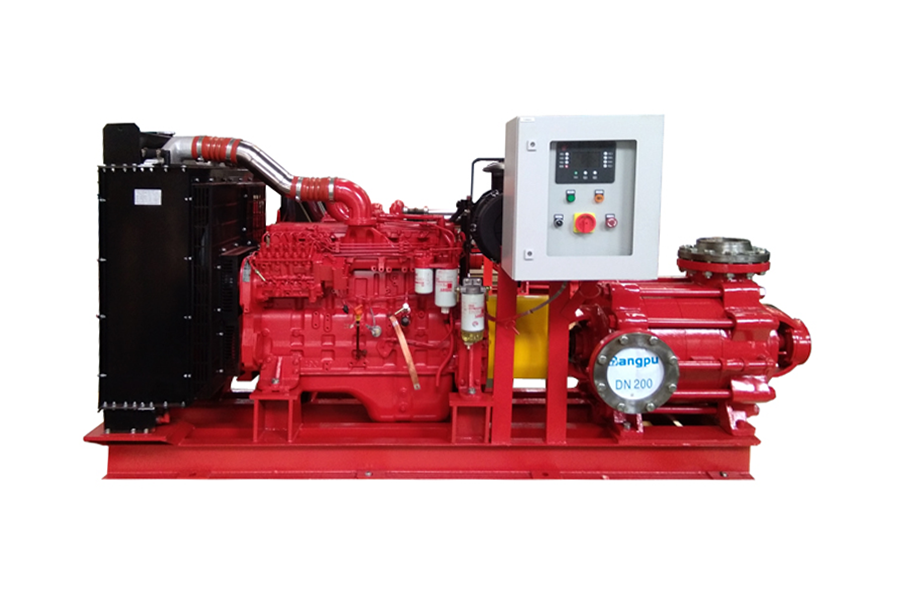

The wear-resistant centrifugal mine water pump can maintain excellent performance when running for a long time and transporting highly abrasive media. In addition to benefiting from the special treatment of high-strength wear-resistant alloy materials and key components, it is also inseparable from its excellent design and technology.

Hydraulic design: The wear-resistant centrifugal mine water pump adopts advanced hydraulic design, which improves the hydrodynamic performance of the pump by optimizing the shape and number of impeller blades, adjusting the structure and layout of the guide vanes, etc. This design enables the water pump to reduce energy consumption and improve efficiency when transporting highly abrasive media, while reducing the erosion and wear of the fluid on the inside of the water pump.

Structural design: The wear-resistant centrifugal mine water pump has a reasonable structural design and is easy to disassemble and repair. All parts of the water pump are tightly connected to ensure that the fluid will not leak during the delivery process. At the same time, wearing parts such as bearings and seals of the water pump adopt standardized designs to facilitate replacement and maintenance.

Manufacturing process: The wear-resistant centrifugal mine water pump has advanced manufacturing technology and is made by precision casting, forging, welding and other processes. These processes can ensure that each part of the water pump has accurate dimensions and standardized shapes, thereby improving the overall performance and durability of the water pump.

The excellent performance and durability of wear-resistant centrifugal mine water pumps not only significantly extend the service life of the equipment, but also bring significant economic benefits and safety production guarantee to coal mining enterprises.

Economic benefits: Due to the high wear resistance and durability of the wear-resistant centrifugal mine water pump, its replacement frequency and maintenance costs are greatly reduced. This reduces the company's equipment purchase and maintenance costs and improves equipment utilization and production efficiency. At the same time, the efficient operation of the water pump reduces energy consumption and operating costs, bringing considerable economic benefits to the enterprise.

Safe production: The excellent performance of the wear-resistant centrifugal mine water pump ensures the stability and reliability of the pump when running for a long time and transporting highly abrasive media. This reduces production downtime and safety hazards caused by water pump failure, providing a strong guarantee for safe production in coal mines.

Application prospects and future prospects

Wear-resistant centrifugal mine water pumps play an irreplaceable role in coal mining with their excellent wear resistance and high efficiency. With the continuous advancement of coal mining technology and the increasing environmental protection requirements, the application prospects of wear-resistant centrifugal mine water pumps will be broader. In the future, wear-resistant centrifugal mine water pumps will develop towards higher efficiency, lower energy consumption, and more environmental protection. At the same time, with the continuous emergence of new materials and new processes, the performance and durability of wear-resistant centrifugal mine water pumps will be further improved, making greater contributions to the sustainable development of coal mining enterprises.

English

English 中文简体

中文简体

Home

Home