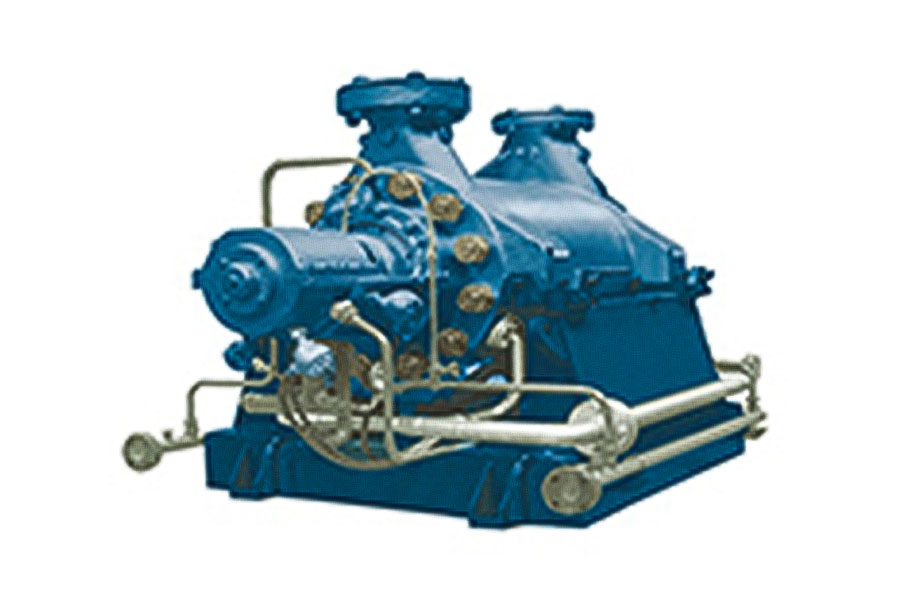

In the chemical production process, the chemical properties of the fluid medium are often extremely complex, including strong acids, strong alkalis, high-temperature steam, corrosive gases, and mixed liquids containing solid particles. These media are extremely corrosive and abrasive to the pump body materials. If the material selection is improper, it is very easy to cause corrosion, deformation, or even failure of the pump body, which in turn affects the safety and efficiency of production. Therefore, the material selection of the horizontal multi-stage chemical process pump not only affects the service life and stability of the pump body, but also directly affects the safety and benefits of the entire chemical production process.

In view of the complexity and diversity of chemical media, the horizontal multi-stage chemical process pump uses a variety of special alloy materials in material selection to ensure the stable operation of the pump body in various harsh environments.

Stainless steel: As one of the most commonly used materials in chemical pumps, stainless steel is widely used in the transportation of various corrosive media with its good corrosion resistance and mechanical strength. Elements such as chromium and nickel are added to stainless steel to form a dense oxide film, which effectively resists the corrosion of the medium. At the same time, stainless steel also has good high temperature resistance and is suitable for the transportation of high-temperature steam.

Titanium alloy: Titanium alloy has become an ideal material for conveying highly corrosive media in chemical pumps due to its high strength, low density and good corrosion resistance. Titanium alloy exhibits excellent corrosion resistance in acidic, alkaline and oxidizing media, and has good processing and welding properties, making it easy to manufacture complex pump body structures.

Hastelloy: Hastelloy is a high-performance corrosion-resistant alloy, especially suitable for conveying high temperature, high pressure and highly corrosive media. Its excellent corrosion resistance, high temperature resistance and high strength make Hastelloy the preferred material for conveying extremely harsh media in chemical pumps.

In addition to the use of special alloy materials, horizontal multi-stage chemical process pumps also use special wear-resistant and impact-resistant coatings or linings for specific media, such as fluids containing solid particles, to improve the service life and stability of the pump.

Wear-resistant coating: For fluids containing solid particles, the inside of the pump body is susceptible to wear and erosion. Therefore, horizontal multi-stage chemical process pumps use wear-resistant coatings in the easily worn parts inside the pump body, such as impellers and pump casings. These coatings are usually made of wear-resistant materials such as ceramics and silicon carbide, with extremely high hardness and wear resistance, and can effectively resist the erosion and wear of solid particles.

Impact-resistant lining: For fluids containing a large amount of solid particles or high-hardness particles, the inside of the pump body may also be subjected to strong impact and vibration. In order to reduce the impact of such impact and vibration on the pump body, the horizontal multi-stage chemical process pump uses an impact-resistant lining inside the pump body. These linings are usually made of elastic materials such as rubber and polyurethane, have good buffering and vibration absorption properties, and can effectively reduce the impact and vibration inside the pump body.

In the material selection process of the horizontal multi-stage chemical process pump, in addition to considering the chemical and physical properties of the medium, it is also necessary to comprehensively consider factors such as the structure, manufacturing process, cost and service life of the pump body. For example, for pump bodies with complex structures and difficult manufacturing, it is necessary to select materials that are easy to process and weld; for projects with high cost requirements, it is necessary to select materials with lower costs as much as possible while ensuring performance; for pump bodies with high service life requirements, it is necessary to select materials with excellent corrosion resistance, high temperature resistance and mechanical strength.

Take a chemical plant as an example. During the production process, the plant needs to transport corrosive media containing a large amount of solid particles. In order to ensure the continuity and safety of production, the plant chose a horizontal multi-stage chemical process pump that combines stainless steel and wear-resistant coating. The pump body is made of stainless steel, which has excellent corrosion resistance and mechanical strength; at the same time, wear-resistant coating is used on the easily worn parts inside the pump body, which effectively resists the erosion and wear of solid particles. After actual operation verification, the pump body shows good stability and durability in harsh environments, effectively extending the service life of the equipment and reducing maintenance costs.

English

English 中文简体

中文简体

Home

Home