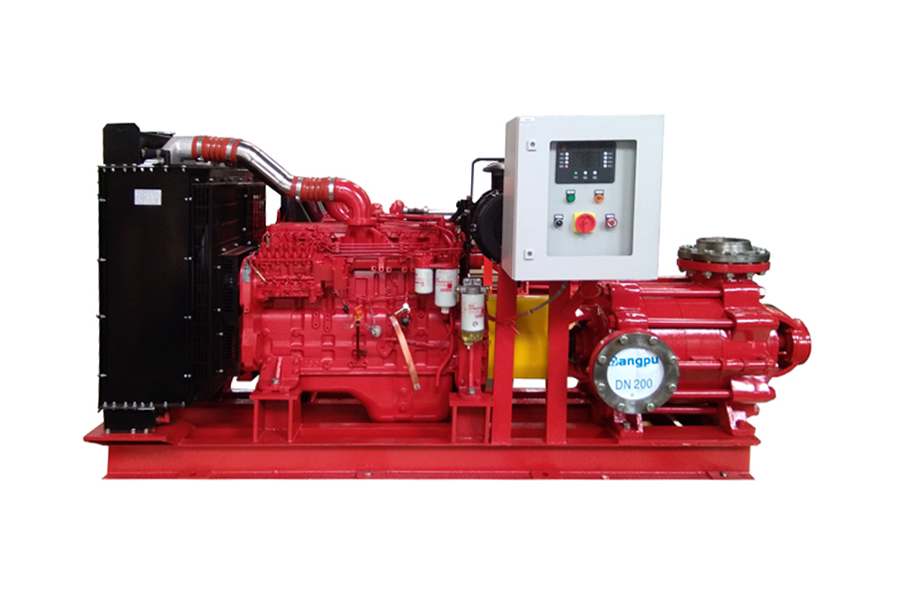

Designing a reliable wearable centrifugal mine water pump is crucial for ensuring the safety and efficiency of mining operations. These pumps play a vital role in dewatering mines, preventing flooding, and maintaining a dry working environment underground. To create a dependable pump for such demanding conditions, several key design considerations must be taken into account. In this comprehensive answer, we will delve into these considerations, emphasizing their importance in creating a reliable and effective centrifugal mine water pump.

Materials Selection:

Material selection is paramount in designing a reliable pump for mine environments. Components exposed to abrasive, corrosive, and abrasive materials must be made from high-quality materials, such as hardened stainless steel, ceramics, or wear-resistant coatings.

The choice of materials should also consider resistance to chemicals commonly found in mine water, including salts, acids, and alkaline substances.

Sealing and Gaskets:

Effective sealing is crucial to prevent water ingress, which could damage internal components and reduce pump efficiency. Mechanical seals or robust gasket systems are essential to maintain a watertight seal in harsh conditions.

Seal redundancy can be incorporated to ensure continued operation in case of seal failure, minimizing downtime.

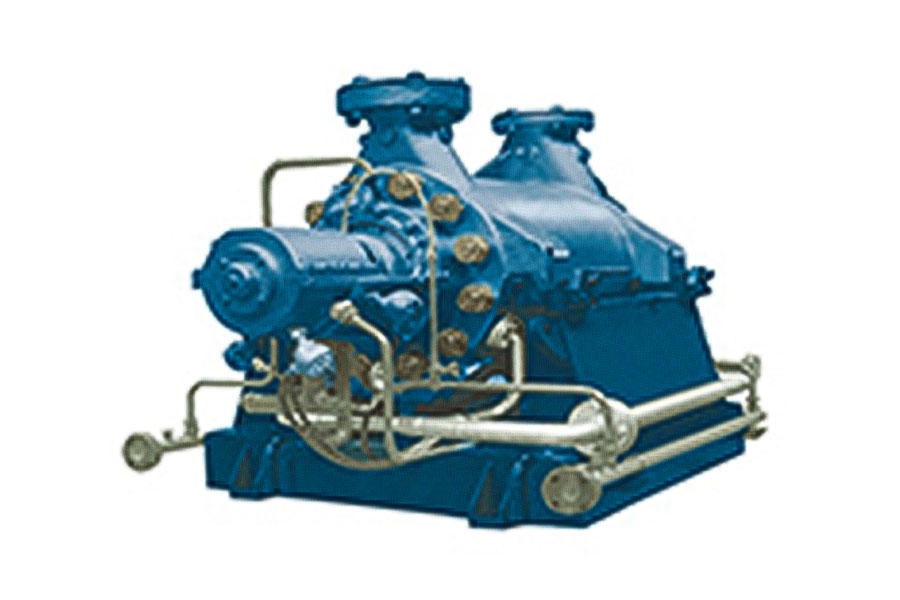

Impeller Design:

The impeller design is a critical factor in a centrifugal pump's performance. It should be optimized to handle abrasive solids and slurry without clogging or excessive wear.

Impellers with a closed or semi-open design can be more suitable for handling solid-laden mine water, while maintaining hydraulic efficiency.

Flow Rate and Head Requirements:

Understanding the specific flow rate and head requirements of the mine is essential for pump sizing and design. The pump must be capable of delivering the required volume of water at the necessary pressure to effectively dewater the mine.

Variable speed drives or adjustable impellers can be incorporated to adapt to changing water conditions.

Efficiency and Energy Consumption:

A reliable mine water pump should be energy-efficient to minimize operational costs. This is especially crucial in remote mining locations where power supply can be limited.

Computational fluid dynamics (CFD) analysis and design optimization can be employed to maximize pump efficiency and reduce energy consumption.

Hydraulic Design:

The pump's hydraulic design should be tailored to the specific characteristics of the mine water. This includes accounting for variations in water temperature, density, and viscosity, as well as any entrained air or gas.

Efficient hydraulic design can reduce cavitation, which can cause damage to the impeller and reduce performance.

Motor and Drive System:

Selecting a reliable motor and drive system is essential. These components must be designed to withstand the harsh operating conditions of a mine, including temperature extremes, dust, and moisture.

Redundant motor systems or backup power sources can be incorporated to ensure continuous operation in case of motor failure.

Ease of Maintenance:

Mine water pumps often require regular maintenance in challenging environments. Design considerations should include accessibility to key components for inspection, repair, and replacement.

Quick-disconnect features and standardized components can facilitate maintenance and minimize downtime.

Environmental Considerations:

Environmental regulations and sustainability goals are increasingly important in mining operations. Pump design should take into account any requirements for water discharge and environmental impact mitigation.

Options for recycling or treating mine water after use can be integrated into the design.

Safety Features:

Safety is paramount in mining. The pump should incorporate safety features such as overheat protection, vibration monitoring, and emergency shutdown systems to protect both equipment and personnel.

Remote Monitoring and Control:

In modern mining operations, remote monitoring and control are highly advantageous. Integration with SCADA (Supervisory Control and Data Acquisition) systems allows for real-time monitoring and adjustment of pump performance.

Predictive maintenance algorithms can also be employed to detect potential issues before they lead to pump failure.

Durability and Longevity:

A wearable centrifugal mine water pump should be designed with durability and longevity in mind. This includes robust construction, effective heat dissipation, and a low-wear design to extend the pump's lifespan.

In conclusion, developing a reliable wearable centrifugal mine water pump involves a complex interplay of materials selection, hydraulic design, efficiency optimization, and safety considerations. Each of these design aspects must be carefully evaluated and tailored to the specific needs of the mining operation. A well-designed pump not only ensures efficient dewatering but also enhances safety, reduces operational costs, and contributes to the overall success and sustainability of mining activities.

English

English 中文简体

中文简体

Home

Home