High voltage motors play a critical role in manufacturing processes by providing the necessary mechanical power to drive various machinery and equipment. Here are some key applications of high voltage motors in manufacturing:

Conveyor Systems: High voltage motors power conveyor belts and systems that transport raw materials, components, and finished products within manufacturing facilities. They ensure a smooth and continuous flow of materials throughout the production process.

Machine Tools: Manufacturing processes often involve machine tools such as lathes, milling machines, and grinders. High voltage motors drive these machines, providing the precision and power required for cutting, shaping, and finishing materials.

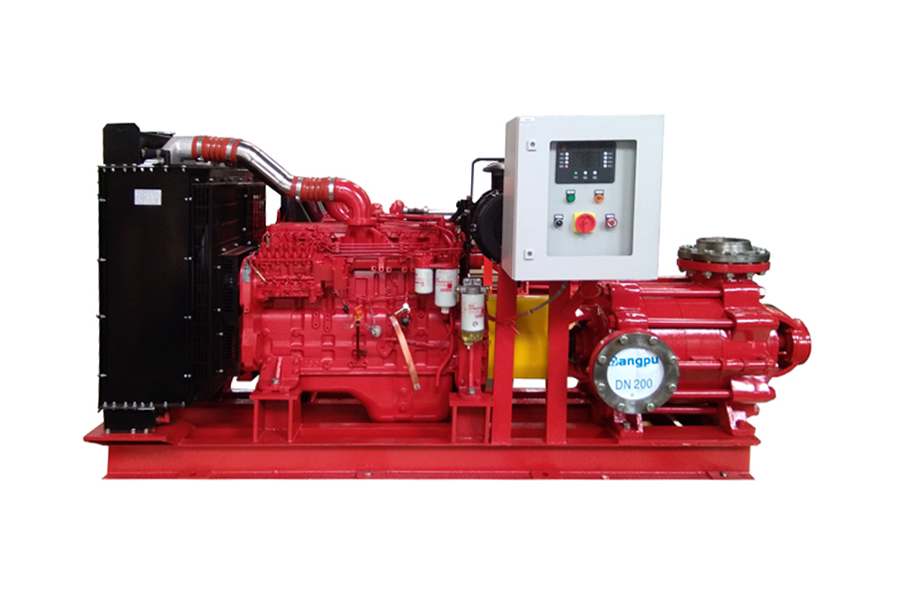

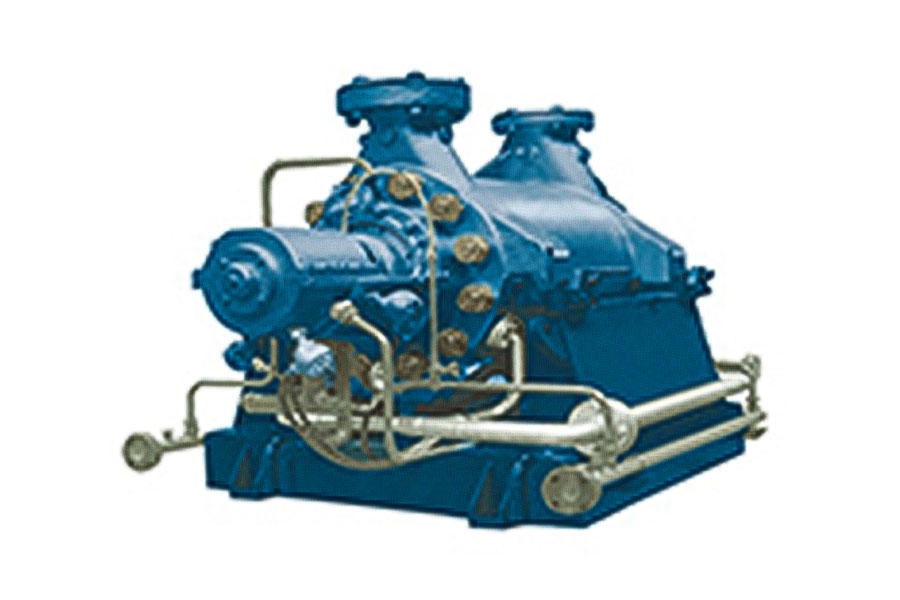

Pumps and Compressors: High voltage motors are used to drive pumps and compressors in manufacturing industries. They are essential for fluid handling, including the movement of liquids and gases for various processes.

Fans and Blowers: In facilities where ventilation and air circulation are crucial, high voltage motors power fans and blowers. These motors ensure proper air quality, temperature control, and the removal of contaminants from the production environment.

Mixers and Agitators: In industries such as pharmaceuticals, chemicals, and food processing, high voltage motors drive mixers and agitators. They facilitate the blending, stirring, and mixing of ingredients or chemicals in large batches.

Material Handling Equipment: Manufacturing often involves the use of material handling equipment like forklifts and cranes. High voltage motors provide the propulsion and lifting power required for moving heavy materials and products.

Packaging Machinery: High voltage motors are used in packaging machinery, including labeling machines, sealing machines, and filling machines. These motors ensure the efficient packaging of products before distribution.

Robotics: In advanced manufacturing processes, industrial robots are becoming increasingly common. High voltage motors are integral to the movement and operation of these robots, enabling precise and efficient automation.

Extruders: Industries like plastics and rubber manufacturing use extruders to shape and mold materials. High voltage motors drive these machines, controlling the flow and shaping of materials as they are forced through a die.

Textile Machinery: In textile manufacturing, high voltage motors drive equipment such as looms, spinning machines, and knitting machines. These motors are crucial for textile production processes.

Paper and Printing Machinery: High voltage motors power paper mills, printing presses, and paper converting machines, allowing for the efficient production of paper products and printed materials.

Metalworking Equipment: High voltage motors are used in metalworking machinery such as presses, roll mills, and metal forming machines. They enable the shaping and processing of metal materials.

Glass Manufacturing: In the glass industry, high voltage motors drive equipment for glass melting, forming, and shaping processes, ensuring precise and controlled manufacturing.

Ceramics Production: High voltage motors are employed in ceramic manufacturing for kilns and other machinery used in the firing and glazing of ceramic products.

Food and Beverage Processing: High voltage motors are used in various stages of food and beverage processing, from mixing and cooking to packaging and labeling.

In summary, high voltage motors are versatile and essential components in manufacturing, powering a wide range of machinery and equipment across various industries. Their reliability, precision, and efficiency contribute to the overall productivity and quality of manufacturing processes.

English

English 中文简体

中文简体

Home

Home