Pump control cabinets are integral components of industrial systems, providing centralized control and monitoring of pumps and related equipment. These cabinets house the electrical and control components necessary to operate and manage pumps efficiently. In this article, we delve into the world of pump control cabinets, highlighting their significance, functionalities, and the advantages they offer in optimizing pump operations and system performance.

Centralized Control and Monitoring:

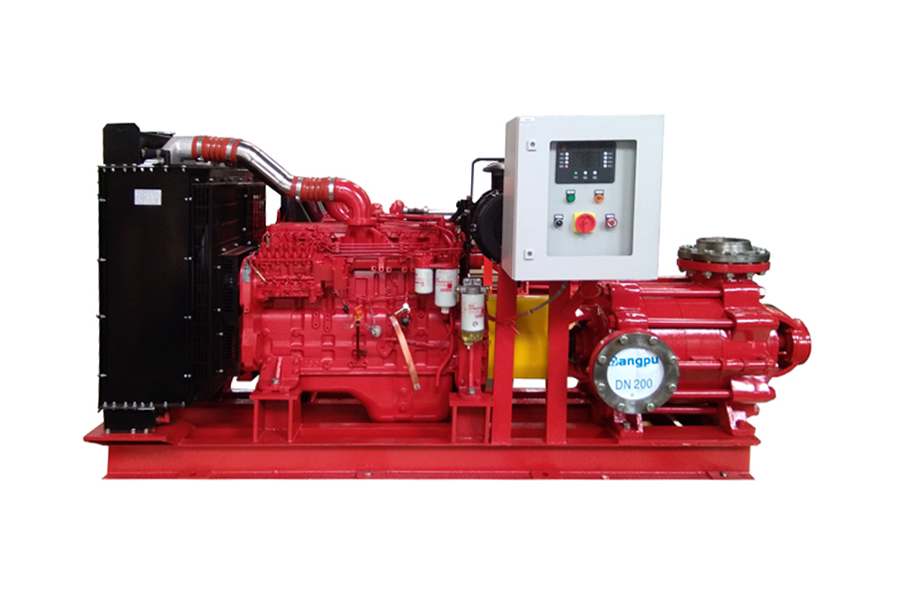

Pump control cabinets serve as a centralized hub for controlling and monitoring pump operations. They house electrical panels, motor starters, variable frequency drives (VFDs), programmable logic controllers (PLCs), and other control devices. This centralized setup allows operators to conveniently regulate pump functions, such as starting, stopping, speed control, and system diagnostics, from a single location. It streamlines operations, simplifies troubleshooting, and facilitates efficient management of pump systems.

Customization and Integration:

Pump control cabinets can be customized and tailored to meet the specific requirements of different industrial applications. They can be designed to integrate seamlessly with existing systems or accommodate future expansions. Customization options include the selection of control devices, communication protocols, alarm systems, and human-machine interfaces (HMIs), ensuring compatibility and optimal functionality within the overall industrial setup.

Enhanced Efficiency and Energy Savings:

The integration of advanced control devices, such as VFDs, within pump control cabinets enables precise speed control and optimization of pump performance. VFDs adjust motor speed based on demand, reducing energy consumption and improving overall system efficiency. With the ability to regulate pump operations based on varying flow rates and pressure requirements, pump control cabinets contribute to significant energy savings and cost reductions over time.

Remote Monitoring and Automation:

Many pump control cabinets offer remote monitoring and automation capabilities. This allows operators to monitor pump performance, receive real-time alerts, and remotely control pump operations from a central control room or even through mobile devices. Remote access and automation enhance operational efficiency, facilitate prompt responses to alarms or malfunctions, and enable proactive maintenance, ultimately reducing downtime and improving system reliability.

System Protection and Safety Features:

Pump control cabinets incorporate various protection and safety features to safeguard pumps and personnel. They include overload protection, short-circuit protection, thermal monitoring, and alarm systems for abnormal conditions. Additionally, these cabinets may feature safety interlocks, emergency stop buttons, and lockout/tagout mechanisms to ensure safe operations, protect equipment from damage, and prevent accidents or hazards.

English

English 中文简体

中文简体

Home

Home