Pump control cabinets play a vital role in the efficient operation and control of fluid management systems. These cabinets, equipped with advanced control and monitoring devices, provide a centralized platform for managing pumps, optimizing performance, and ensuring reliable operation. In this article, we will explore the importance of pump control cabinets, their key features, and the benefits they offer in various industries and applications.

Understanding Pump Control Cabinets:

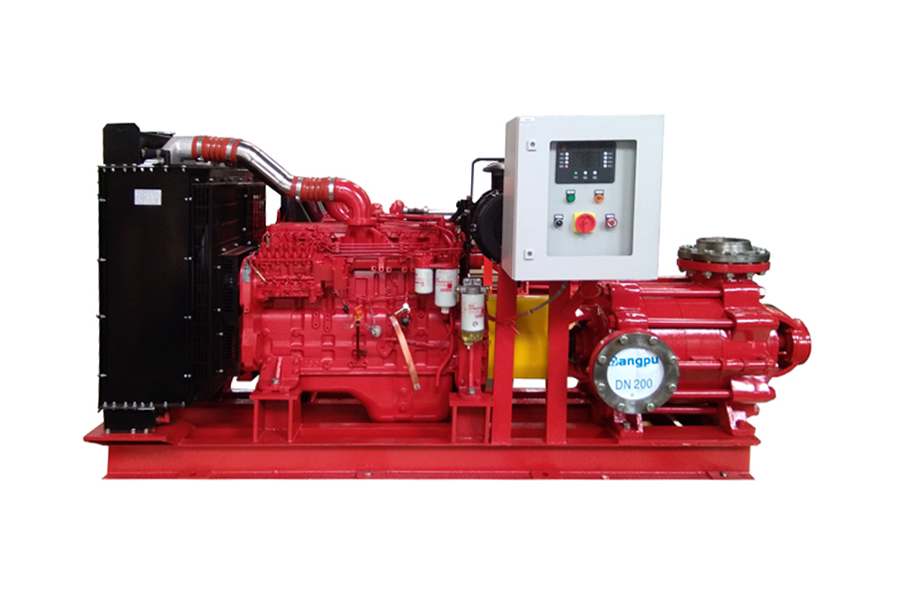

A pump control cabinet serves as a centralized control panel that houses the necessary electrical components, control devices, and monitoring systems for pump operation. It provides a safe and organized space for managing and monitoring the performance of pumps in fluid management systems.

Key Features and Functionality:

Pump control cabinets encompass several essential features and functionalities:

a) Motor Control: Pump control cabinets include motor starters and motor protection devices that enable precise control and protection of the pump motors. These devices ensure optimal motor performance, prevent overloading, and safeguard against electrical faults.

b) Control and Monitoring Systems: Advanced control systems integrated into pump control cabinets allow for centralized monitoring and control of pump operation. These systems provide real-time data on flow rates, pressure, temperature, and other parameters, enabling operators to adjust pump settings as needed.

c) Variable Frequency Drives (VFDs): Many pump control cabinets incorporate variable frequency drives, which allow for precise control of pump speed and motor output. VFDs offer energy-saving benefits by adjusting pump operation based on demand, reducing power consumption, and extending equipment lifespan.

d) Alarm and Safety Systems: Pump control cabinets feature alarm systems that alert operators to potential issues such as pump failure, low pressure, or high temperature. These safety systems help prevent damage to pumps, minimize downtime, and ensure safe operation.

e) Remote Monitoring and Control: Some advanced pump control cabinets offer remote monitoring and control capabilities, allowing operators to access and manage pump operations from a centralized location or even remotely. This feature enhances convenience, efficiency, and the ability to address potential issues promptly.

Benefits of Pump Control Cabinets:

The utilization of pump control cabinets offers several advantages:

a) Enhanced Efficiency: Pump control cabinets enable precise control of pump operation, allowing for optimal energy usage and efficient fluid management. The ability to adjust pump speed and output based on demand minimizes energy wastage and reduces operating costs.

b) Improved System Performance: The centralized monitoring and control provided by pump control cabinets ensure consistent and reliable pump performance. Operators can closely monitor parameters, detect abnormalities, and make necessary adjustments to maintain optimal system operation.

c) Maintenance and Troubleshooting Ease: Pump control cabinets provide a centralized location for monitoring and managing pump performance, simplifying maintenance tasks and troubleshooting procedures. Operators can easily access diagnostic information, perform routine maintenance, and address issues promptly.

d) System Protection: The advanced safety features integrated into pump control cabinets help protect pumps from damage caused by issues such as power surges, overloads, or system malfunctions. This protection extends the lifespan of the pumps and reduces the risk of costly repairs or replacements.

e) Scalability and Adaptability: Pump control cabinets are designed to accommodate the specific needs of fluid management systems. They can be tailored to different pump types, capacities, and control requirements, allowing for scalability and adaptability to varying system demands.

Pump control cabinets serve as the nerve center of fluid management systems, providing efficient control, monitoring, and protection for pumps. With their advanced features, centralized operation, and real-time data monitoring, these cabinets optimize pump performance, reduce energy consumption, and enhance system reliability. Incorporating pump control cabinets into fluid management systems is a prudent investment, yielding improved efficiency, reduced maintenance costs, and enhanced operational control.

English

English 中文简体

中文简体

Home

Home