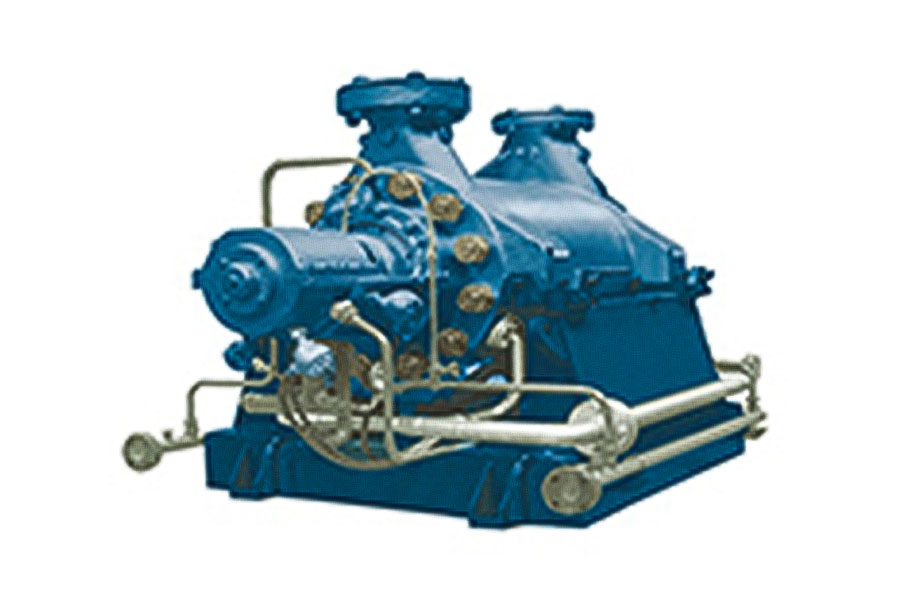

In the field of fluid machinery, the single-stage double-suction centrifugal pump has become a leader in many industrial applications with its unique double-suction structure and optimized design. Among them, smooth operation, as another highlight of this pump type, not only improves the overall performance of the pump, but also brings users a more reliable and efficient use experience.

The core of the single-stage double-suction centrifugal pump lies in its unique double-suction impeller design. This design concept is proposed to solve the vibration and noise problems caused by the unbalanced axial force during the operation of traditional single-suction centrifugal pumps. The double-suction structure, as the name suggests, means that the water flow enters from both sides of the impeller at the same time. This layout method fundamentally changes the distribution of the force of the fluid on the impeller.

In the double-suction impeller, the water flow is evenly distributed to both sides of the impeller, and the water flow on each side exerts a centripetal force on the impeller. Because the forces on both sides are equal in magnitude and opposite in direction, they cancel each other out, thereby effectively balancing the axial force. This balancing mechanism not only reduces the vibration of the pump, but also reduces the noise generated by vibration, providing a strong guarantee for the stable operation of the pump.

The design of the double-suction impeller is only the first step to achieve smooth operation. Behind it are more complex fluid dynamics principles and structural optimization technologies. During the operation of the pump, when the water flows through the double-suction impeller, it will be accelerated and converted into pressure energy, and then discharged through the pump casing. In this process, factors such as the rotation speed of the impeller, the shape and angle of the blades, and the flow channel design of the pump casing will have an important impact on the performance of the pump.

In order to ensure the smooth operation of the pump, engineers need to perform detailed calculations and simulations on these factors, and continuously optimize the design parameters so that the pump can maintain a stable flow and pressure output under different working conditions. At the same time, strict quality control is also required for the manufacturing and assembly process of the pump to ensure that each component meets the design requirements, thereby ensuring the overall performance of the pump.

The smooth operation of the single-stage double-suction centrifugal pump is not only reflected in reducing vibration and noise, but also brings multiple advantages, which are fully reflected in many fields.

Improve operating efficiency: Since the double-suction impeller effectively balances the axial force and reduces the mechanical loss of the pump, the pump can be more efficient when conveying fluids. This not only reduces energy consumption, but also improves production efficiency, bringing significant economic benefits to users.

Extended service life: The reduction in vibration and noise means that the impact and wear of the internal parts of the pump will also be reduced accordingly. This helps to extend the service life of the pump, reduce the frequency of repair and replacement of parts, and reduce the maintenance cost of users.

Enhanced reliability: A pump that runs smoothly can maintain stable operation under harsh working conditions and is not prone to failure and shutdown. This high reliability is particularly important for key equipment that needs to run continuously, which can ensure the stable operation of the production line and the stable output of product quality.

Improve user experience: For operators, a pump that runs smoothly reduces the interference of noise and vibration and improves the comfort of the working environment. At the same time, it reduces the inconvenience and loss caused by downtime due to failures, and improves the overall satisfaction of users.

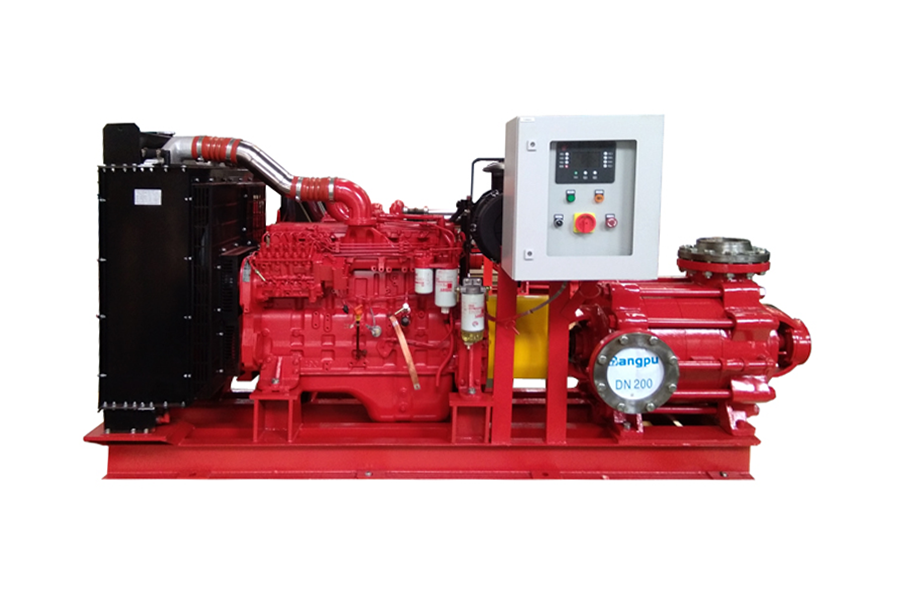

Single-stage double-suction centrifugal pumps have been widely used in many fields due to their excellent running stability. In the power, metallurgy, petrochemical, municipal and other industries, it is an important fluid conveying equipment, providing reliable fluid power support for various process processes. At the same time, with the continuous advancement of industrial technology and the increasing requirements for energy conservation and emission reduction, single-stage double-suction centrifugal pumps are also constantly innovating technology and optimizing performance to meet more complex and diverse working conditions.

Single-stage double-suction centrifugal pumps are expected to achieve further development in the following aspects: First, improve the efficiency and reliability of the pump, and achieve a leap in pump performance by adopting more advanced materials and manufacturing processes; second, expand the application field and expand the application range of the pump to more emerging industries and fields; third, strengthen the application of intelligent and automated technologies, and realize remote monitoring and intelligent adjustment of the pump by integrating intelligent devices such as sensors and controllers, so as to improve the operation efficiency and management level of the pump.

Single-stage double-suction centrifugal pumps, with their unique double-suction impeller design and excellent running stability, have shown strong competitiveness and broad application prospects in the field of fluid machinery. With the continuous advancement of technology and the continuous expansion of the market, we have reason to believe that single-stage double-suction centrifugal pumps will play a more important role in the future and contribute more to industrial development and social progress.

English

English 中文简体

中文简体

Home

Home