In the world of fluid machinery, vertical axial flow pump has become the core equipment in many industries with its unique design concept and excellent performance. Its efficient and stable fluid delivery capacity is inseparable from the precision cooperation between internal components, especially the key combination of plunger and plunger sleeve. The tacit cooperation between them is like the main melody in a symphony, leading the efficient operation of the entire pump body.

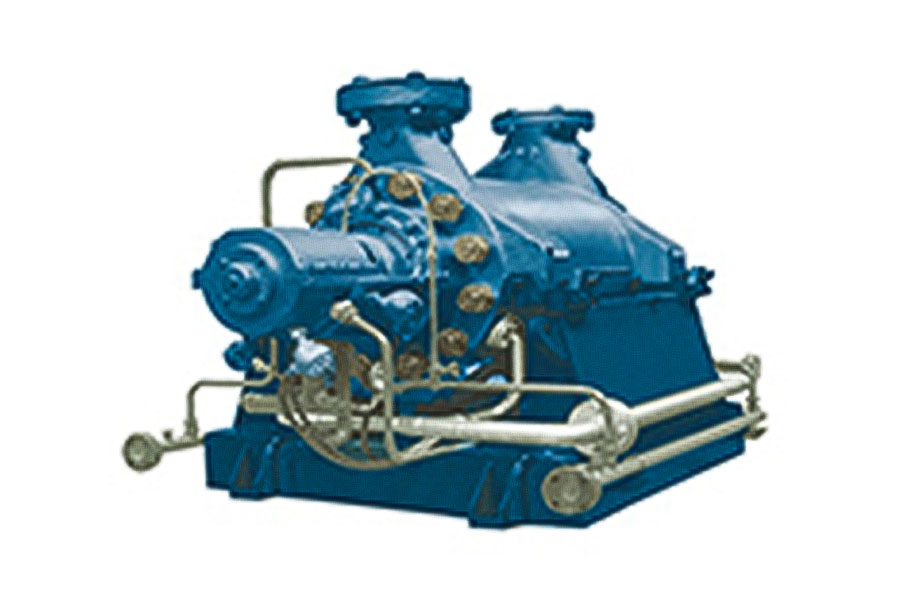

In the internal structure of the vertical axial flow pump, the plunger sleeve is not only an important component to support and guide the plunger, but also the starting point for the fluid to enter the pump body and start its power journey. The small holes on the plunger sleeve, these seemingly insignificant details, actually contain the crystallization of profound fluid dynamics principles and precision machining technology.

The position, size and shape of the small holes are determined by strict calculation and repeated testing based on the principles of fluid mechanics. Their position layout must ensure that during the movement of the plunger, the resistance and turbulence of the fluid flow can be minimized, so that the fluid can enter the plunger sleeve smoothly and efficiently. At the same time, the size and shape of the small hole must also take into account the needs of flow and pressure, ensuring sufficient fluid inflow to meet the working needs of the pump body, and avoiding excessive flow that causes pressure fluctuations and energy loss.

When the plunger begins to rise under the action of the driving force, the precise cooperation between it and the plunger sleeve begins a silent dance. The rise of the plunger is not only a compression process of the fluid, but also a key link in energy conversion and accumulation. As the plunger gradually rises, the fluid in the plunger sleeve is gradually compressed, and its pressure and temperature also increase accordingly.

In this process, the sealing and wear resistance between the plunger and the plunger sleeve are particularly important. Insufficient sealing will cause fluid leakage and reduce the efficiency of the pump body; while poor wear resistance will cause wear during long-term operation, affecting the stability and life of the pump body. Therefore, the material selection, processing accuracy and surface treatment of the plunger and the plunger sleeve must be strictly screened and tested to ensure that they can maintain stable performance in harsh working environments.

After the fluid enters the pump body from the small hole on the plunger sleeve, it begins its power journey in the pump body. In a vertical axial flow pump, the fluid will flow along a specific flow channel and gain kinetic energy and potential energy under the impeller's push. In this process, the principles of fluid dynamics are fully utilized, and efficient fluid delivery and energy conversion are achieved by optimizing the flow channel design and adjusting the impeller parameters.

When the fluid is compressed and accelerated, it will be transported to the target location through the outlet pipe of the pump body. In this process, the vertical axial flow pump not only realizes the long-distance delivery of the fluid, but also provides strong support for the production and life of all walks of life through its efficient and stable performance.

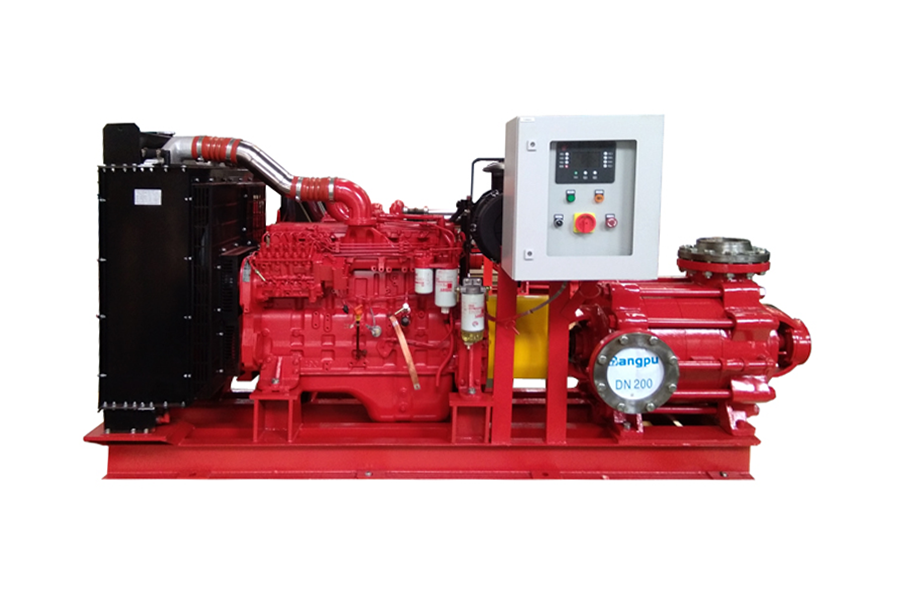

Thanks to its excellent performance and wide application adaptability, vertical axial flow pumps have been widely used in agriculture, industry, urban water supply, flood control and drainage and other fields. In agricultural irrigation, the vertical axial flow pump provides a stable water source guarantee for the vast farmland with its large flow and high head; in the industrial field, it has become one of the important equipment in the production process of chemical, metallurgical, papermaking and other industries; and in urban water supply and flood control and drainage, the vertical axial flow pump provides a strong guarantee for the normal operation of the city and the safe life of residents with its powerful drainage capacity and efficient operation efficiency.

As an important member in the field of fluid machinery, the vertical axial flow pump reveals the mystery of fluid dynamics and the wisdom of mechanical design through the precise cooperation and efficient operation of its internal components. In the future development, with the continuous advancement of science and technology and the improvement of manufacturing technology, we have reason to believe that the vertical axial flow pump will play a greater role in more fields and contribute more to the sustainable development of human society. At the same time, the research and optimization of the key combination of plunger and plunger sleeve will continue to deepen to promote the continuous progress and innovation of vertical axial flow pump technology.

English

English 中文简体

中文简体

Home

Home