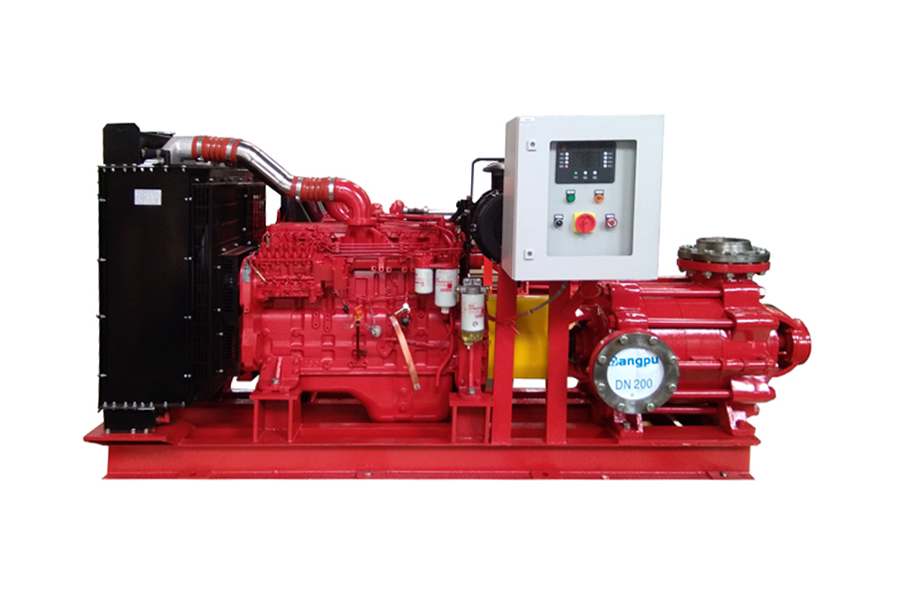

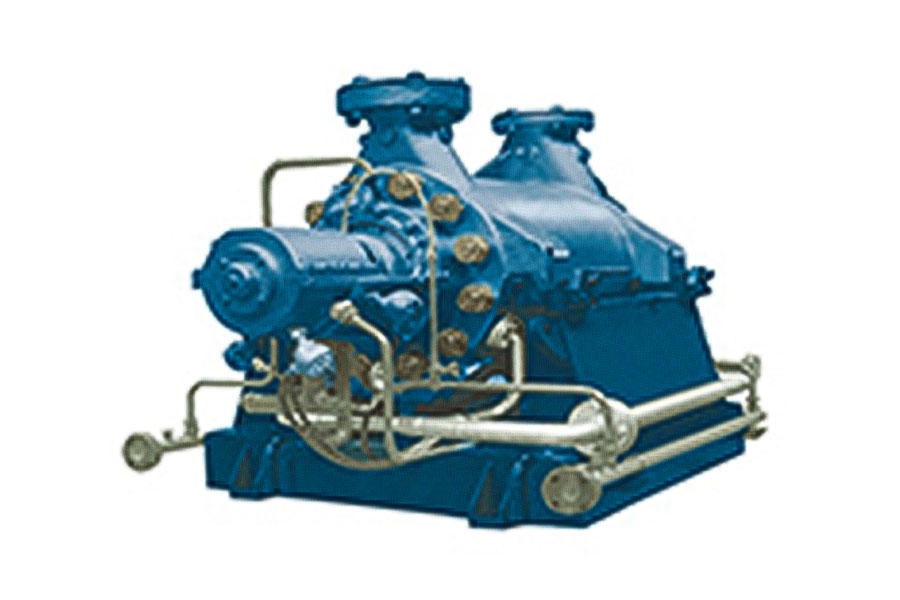

A horizontal multistage chemical process pump is a type of pump used to transfer chemicals from one location to another. This type of pump is designed to handle a wide range of chemicals, including corrosive and abrasive substances. In this article, we will take a closer look at horizontal multistage chemical process pumps, including their design, features, and applications.

Design

Horizontal multistage chemical process pumps are designed with multiple stages that work together to transfer fluids. Each stage includes an impeller that rotates and moves fluid from the suction side of the pump to the discharge side. The impellers are typically made of stainless steel or other corrosion-resistant materials to prevent damage from the chemicals being transferred.

The pump casing is also designed to withstand chemical exposure, typically constructed of materials such as cast iron, stainless steel, or plastic. The pump shaft is usually made of stainless steel, and the bearings are designed to handle the high radial and axial loads generated by the impellers.

Features

Horizontal multistage chemical process pumps typically have several key features that make them suitable for transferring chemicals. Some of these features include:

High Efficiency: These pumps are designed to operate with high efficiency, which means that they can transfer large volumes of fluid using less energy.

Low NPSHr: Horizontal multistage chemical process pumps have a low net positive suction head required (NPSHr), which means that they can operate with low inlet pressures.

Wide Range of Flow Rates: These pumps can handle a wide range of flow rates, making them suitable for a variety of applications.

Low Maintenance: The simple design of these pumps means that they require minimal maintenance and can operate for long periods without issues.

Applications

Horizontal multistage chemical process pumps are used in a wide range of applications, including:

Chemical Processing: These pumps are commonly used in chemical processing plants to transfer chemicals from one location to another.

Water Treatment: They are used in water treatment facilities to transfer chemicals used in the treatment process.

Pharmaceutical Manufacturing: These pumps are used in pharmaceutical manufacturing to transfer chemicals and ingredients during the production process.

Food and Beverage Production: They are also used in the food and beverage industry to transfer ingredients and additives.

Horizontal multistage chemical process pumps are essential in the transfer of chemicals in various industrial processes. These pumps are designed to handle a wide range of chemicals, and their high efficiency, low NPSHr, wide range of flow rates, and low maintenance requirements make them an ideal choice for many applications. If you're in the market for a pump for your chemical transfer needs, a horizontal multistage chemical process pump could be the perfect solution.

English

English 中文简体

中文简体

Home

Home