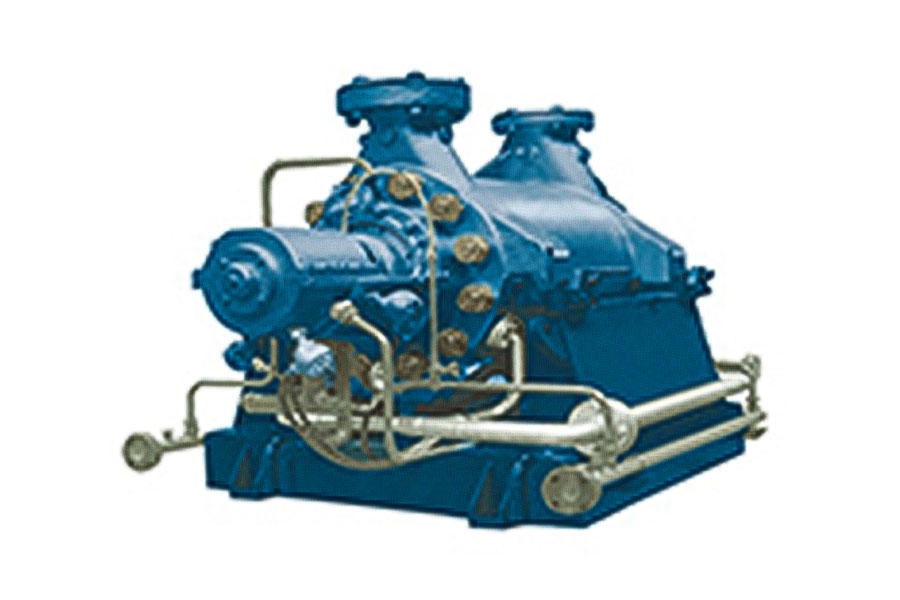

Horizontal Multistage Chemical Process Pumps offer several key features and advantages that make them well-suited for various industrial applications:

High Pressure and Flow Capacity: These pumps are designed to handle high pressures and deliver substantial flow rates, making them ideal for transferring large volumes of fluids over long distances in industrial processes.

Multistage Design: The pump's multistage configuration involves multiple impellers arranged in series, each increasing the pressure of the fluid as it passes through. This design allows the pump to generate higher pressures than single-stage pumps, which is crucial for many chemical processes.

Efficient Energy Usage: Despite their ability to generate high pressures, these pumps are designed for energy efficiency, ensuring optimal performance while minimizing power consumption and operational costs.

Corrosion Resistance: Horizontal Multistage Chemical Process Pumps are built with materials that offer excellent resistance to corrosion from aggressive and corrosive chemicals commonly encountered in industrial applications. This corrosion resistance ensures the longevity and reliability of the pump.

Versatility: These pumps are highly versatile and can handle a wide range of chemical fluids, including aggressive, volatile, and abrasive substances. They find applications in various industries, such as chemical processing, petrochemical, pharmaceuticals, water treatment, and more.

Compact Design: The horizontal orientation of the pump, coupled with its compact design, allows for easier installation and saves valuable floor space in industrial settings.

Low NPSH Requirement: Net Positive Suction Head (NPSH) is the minimum pressure required at the pump inlet to prevent cavitation. Horizontal Multistage Chemical Process Pumps typically have low NPSH requirements, reducing the risk of cavitation and ensuring stable operation.

Reliable Operation: With robust construction and precision engineering, these pumps offer reliable and continuous operation, reducing downtime and maintenance costs in industrial processes.

Easy Maintenance: Manufacturers often design these pumps with user-friendly features, making maintenance tasks, such as impeller or seal replacement, straightforward, thereby reducing downtime and ensuring the pump operates optimally.

Safe Handling of Hazardous Fluids: Horizontal Multistage Chemical Process Pumps are specifically engineered to meet strict safety standards, allowing for the safe handling and transfer of hazardous chemicals, which is crucial in industrial environments.

Overall, the combination of high pressure capacity, corrosion resistance, energy efficiency, and versatility makes Horizontal Multistage Chemical Process Pumps a reliable and preferred choice for handling chemical fluids in various industrial applications.

English

English 中文简体

中文简体

Home

Home