In the busy and tense chemical production site, machine roars and pipeline vibrations are common phenomena. However, these seemingly ordinary vibrations and noises not only affect the comfort of the working environment, but may also pose a potential threat to the physical and mental health of front-line workers. In such a context, the horizontal multi-stage chemical process pump has become a silent guardian in chemical production with its vibration and noise reduction capabilities.

In the chemical production process, various equipment will produce varying degrees of vibration and noise when running at high speed. Long-term exposure to this environment will not only cause worker fatigue and distraction, but may also cause hearing loss, headaches, insomnia and other health problems. Therefore, reducing vibration and noise is crucial to improving the quality of the working environment and protecting the health of workers.

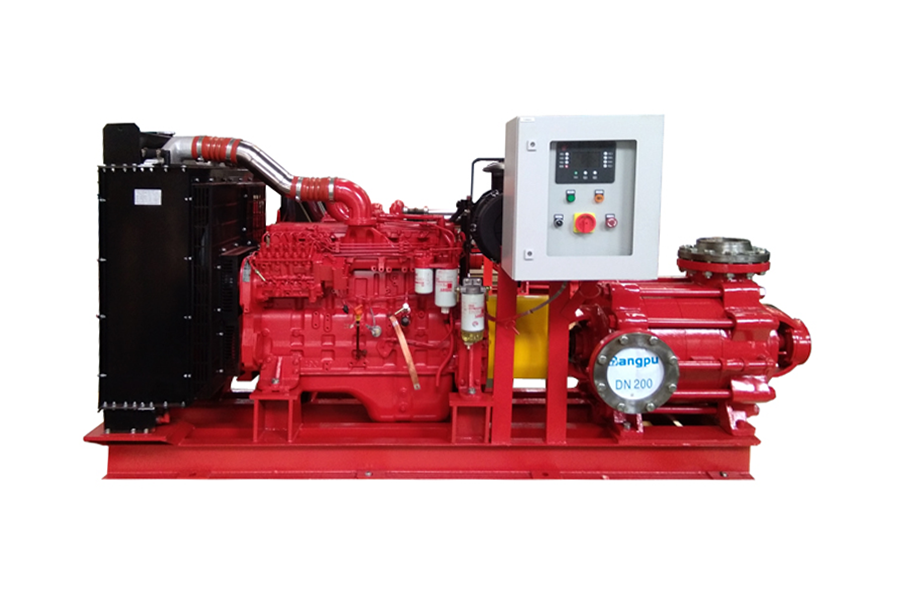

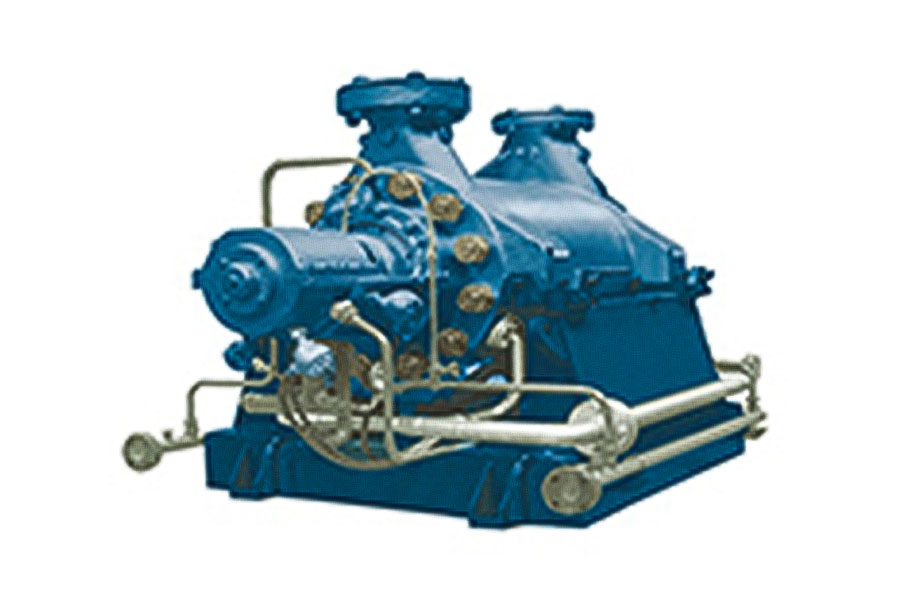

The horizontal multi-stage chemical process pump performs well in vibration and noise reduction with its balance design. Its horizontal installation method enables each part of the pump body to maintain a relatively stable state of motion during operation, effectively reducing equipment damage and performance degradation caused by vibration. At the same time, the structural optimization and material selection inside the pump body also further enhance its ability to reduce vibration and noise. These optimization measures make the horizontal multi-stage chemical process pump quieter and smoother during operation, providing workers with a comfortable working environment.

The silent characteristics of the horizontal multi-stage chemical process pump not only improve the working environment, but also indirectly improve work efficiency. In a quiet working environment, workers can concentrate more on operation and monitoring, reducing errors and accidents caused by noise interference. At the same time, the stable operation of the pump body also ensures the smooth delivery of the fluid, further improving the overall operation efficiency of the production line.

In addition to the ability to reduce vibration and noise, the horizontal multi-stage chemical process pump also has strong adaptability. It can transport fluids of various corrosive, flammable, explosive, high-viscosity and other complex media to meet the needs of different chemical production processes. In addition, by adjusting the number and arrangement of impellers and guide vanes, the horizontal multi-stage chemical process pump can adapt to the needs of different flow rates and lifts, providing a more flexible and efficient solution for chemical production.

The horizontal multi-stage chemical process pump plays an important role in chemical production with its vibration and noise reduction capabilities and adaptability. It is not only a silent guardian in chemical production, but also an important tool to improve the quality of the working environment and protect the health of workers. With the continuous advancement of technology and the continuous expansion of applications, horizontal multi-stage chemical process pumps will continue to play a more important role in the chemical industry and contribute to the sustainable development of chemical production.

English

English 中文简体

中文简体

Home

Home