With the acceleration of urbanization and the expansion of industrial activities, sewage treatment faces unprecedented challenges. On the one hand, the complex components such as solid particles, grease, and chemicals contained in sewage put forward extremely high requirements for treatment equipment; on the other hand, reducing the retention time of sewage in the system and reducing the potential threat of pollutants to the environment have become key issues that need to be urgently solved in the field of sewage treatment. In this context, self-priming centrifugal pumps have become an important choice in the field of sewage treatment with their unique technical advantages.

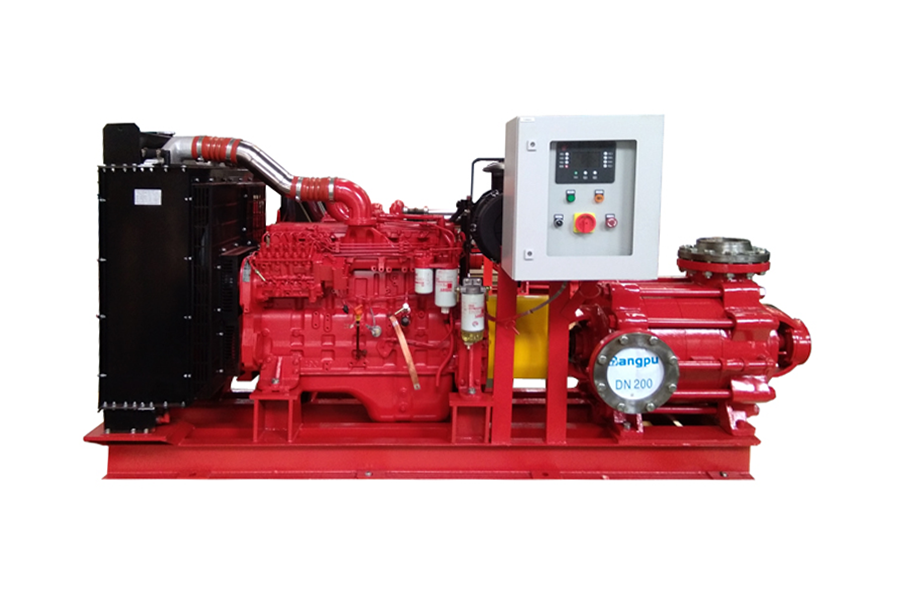

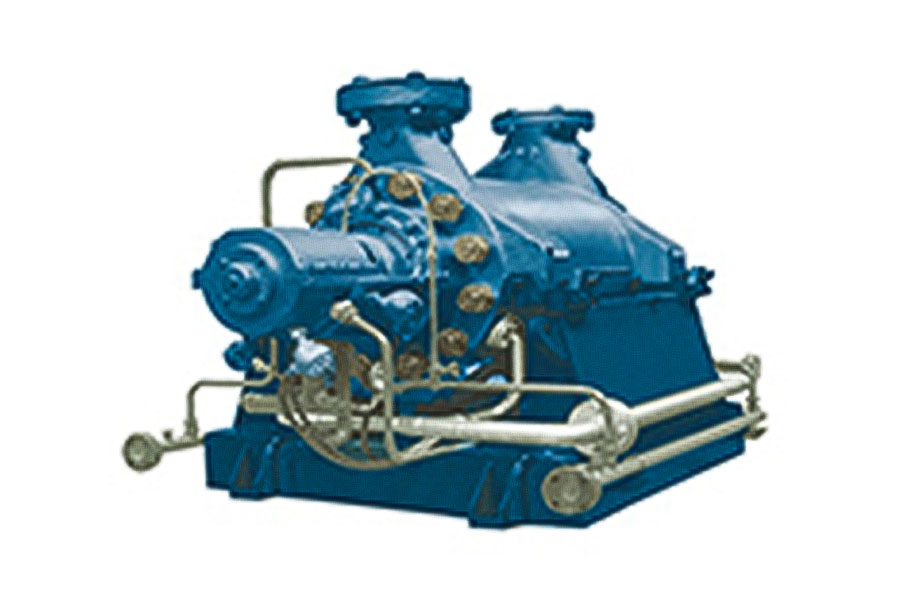

The core advantage of self-priming centrifugal pumps lies in their strong drainage capacity. Through optimized hydraulic design and efficient motor drive, self-priming centrifugal pumps can quickly suck in sewage and discharge it efficiently, greatly shortening the retention time of sewage in the system. This feature not only reduces the accumulation of sewage in pipes and storage tanks, reduces the risk of bacterial growth and pollutant spread, but also improves the operating efficiency of the entire sewage treatment system. In peak periods or emergency situations, the rapid response capability of self-priming centrifugal pumps provides a strong guarantee for the stable operation of sewage treatment systems.

In the process of sewage treatment, sewage often contains complex components such as solid particles, grease, acid and alkali substances, which pose a severe test to the treatment equipment. The design of the self-priming centrifugal pump fully considers the special needs of sewage treatment. It adopts corrosion-resistant materials such as stainless steel and titanium alloy, as well as special anti-clogging structural designs such as cutting impellers and large channel designs, ensuring stable operation when treating sewage containing complex components such as solid particles and grease. These designs not only extend the service life of the self-priming centrifugal pump, but also improve the efficiency and safety of sewage treatment, and reduce downtime and maintenance costs caused by equipment failure.

With the rapid development of technologies such as the Internet of Things, big data, and artificial intelligence, self-priming centrifugal pumps are also gradually realizing intelligent upgrades. Through integrated sensors, remote monitoring and intelligent control systems, self-priming centrifugal pumps can monitor key parameters such as operating status, flow, and pressure in real time, and automatically adjust the working mode according to actual needs to achieve precise control. This not only improves the efficiency and stability of sewage treatment, but also reduces energy consumption and operating costs. At the same time, intelligent self-priming centrifugal pumps can also realize remote fault diagnosis and early warning, which provides great convenience for equipment maintenance and management.

Self-priming centrifugal pumps are widely used in the field of sewage treatment, covering many fields such as urban sewage treatment plants, industrial wastewater treatment stations, and agricultural irrigation systems. Taking the urban sewage treatment plant as an example, the efficient drainage capacity, corrosion resistance and anti-clogging characteristics of the self-priming centrifugal pump enable the sewage treatment plant to treat a large amount of sewage more quickly, reducing pollution to the environment. At the same time, the intelligent self-priming centrifugal pump can also automatically adjust the working parameters according to the changes in sewage flow and composition to ensure the stability and efficiency of the sewage treatment process. This not only improves the operating efficiency of the sewage treatment plant, but also reduces the operating costs, making an important contribution to urban environmental protection and water resources management.

In industrial wastewater treatment stations, self-priming centrifugal pumps also play a key role. Since industrial wastewater often contains high concentrations of chemicals, heavy metal ions and other harmful substances, the requirements for treatment equipment are extremely high. The corrosion resistance and anti-clogging characteristics of the self-priming centrifugal pump enable it to stably treat industrial wastewater containing complex components such as solid particles and grease, effectively reducing the potential threat of wastewater to the environment. At the same time, the intelligent control system can also monitor the wastewater treatment process in real time to ensure that the wastewater treatment meets the emission standards, providing strong support for the sustainable development of industry.

English

English 中文简体

中文简体

Home

Home