A non-seal self-control self-suction pump, often referred to as a self-priming pump, represents a significant departure from traditional pump designs in terms of its operation and functionality. To understand the differences, it's essential to delve into the characteristics and working principles of both types of pumps.

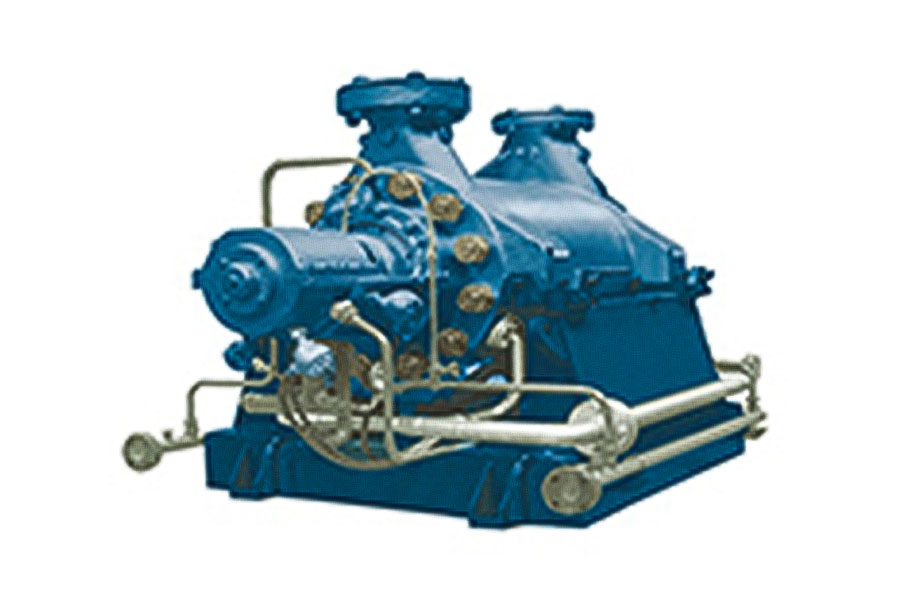

Traditional Pump

Traditional pumps, such as centrifugal pumps, diaphragm pumps, and reciprocating pumps, rely on a mechanical seal or packing gland to prevent fluid leakage from the pump chamber. These seals serve a crucial function in maintaining the integrity of the pump and ensuring that the pumped fluid doesn't escape into the environment.

Here are some key characteristics of traditional pumps:

Seals or Glands: Traditional pumps use seals or packing glands, which are typically made of materials like rubber or graphite, to prevent leakage. These components require regular maintenance and replacement as they wear out over time.

Dependence on External Priming: Most traditional pumps require external priming to start the pumping process. This means that the pump's casing and suction line must be filled with the fluid being pumped before operation, which can be cumbersome and time-consuming.

Limited Dry Running Capability: Traditional pumps are sensitive to running without the presence of the pumped fluid, which can lead to damage or overheating if the fluid supply is interrupted.

Risk of Leakage: Because traditional pumps rely on seals, there is a risk of fluid leakage, especially when handling corrosive, abrasive, or hazardous substances. This poses environmental and safety concerns.

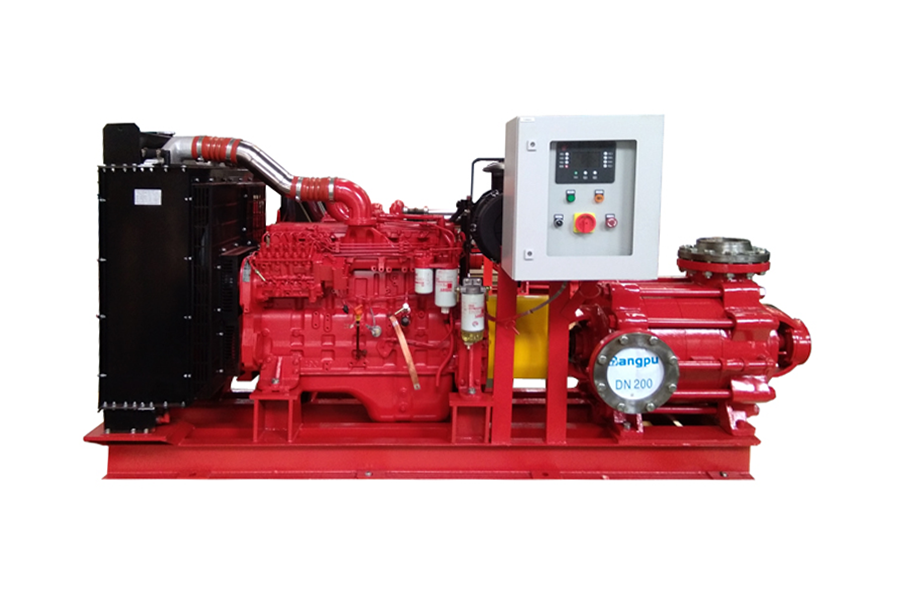

Non-Seal Self-Control Self-Suction Pump

In contrast, non-seal self-control self-suction pumps, also known as self-priming pumps, have several distinct features that set them apart:

Self-Priming Capability: One of the most significant differences is their ability to self-prime, meaning they can start pumping without the need for external priming. This makes them ideal for applications where the fluid source is distant or not continuous.

Absence of Seals: Non-seal self-control self-suction pumps do not rely on mechanical seals or packing glands to prevent leakage. Instead, they use innovative design features and mechanisms to maintain a seal-free operation.

Dry Running Tolerance: These pumps can handle periods of dry running without sustaining damage, which is advantageous in situations where the fluid supply may fluctuate or be intermittent.

Reduced Maintenance: Because they lack traditional seals that wear out, non-seal self-control self-suction pumps often require less maintenance over time. This can lead to cost savings and increased operational efficiency.

Enhanced Safety: The absence of seals reduces the risk of fluid leakage, which is crucial when handling hazardous or toxic substances. It also minimizes the risk of environmental contamination.

The key to the self-priming capability of these pumps lies in their design, which typically includes a unique casing and impeller arrangement. Here's how a non-seal self-control self-suction pump works:

When the pump is started, the impeller generates a centrifugal force that creates a partial vacuum in the suction line.

This vacuum draws air and fluid from the suction line into the pump chamber.

As the mixture of air and fluid enters the pump chamber, it is mixed and compressed.

The compressed mixture is then forced out of the pump, effectively priming the pump and allowing it to operate normally.

This self-priming process can happen quickly, often within a matter of seconds, and without any external intervention. It ensures that the pump remains primed even when there are interruptions in the fluid supply.

Non-seal self-control self-suction pumps find application in a wide range of industries, including agriculture, construction, wastewater management, and oil and gas. Their ability to handle challenging fluid-handling situations, reduce maintenance requirements, and enhance safety makes them valuable assets in many industrial and commercial settings.

In conclusion, a non-seal self-control self-suction pump differs significantly from traditional pumps by eliminating the need for mechanical seals, offering self-priming capabilities, tolerating dry running, and reducing maintenance and safety concerns. These differences make self-priming pumps a preferred choice for various applications where reliable and efficient fluid handling is essential.

English

English 中文简体

中文简体

Home

Home